LUOYANG DATANG ENERGY TECH CO.,LTD

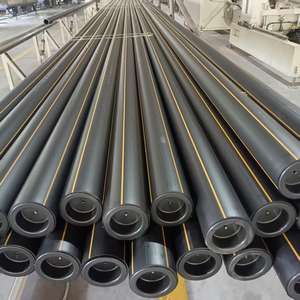

Whole Plastic Underground Petroleum Pipe for Petrol Gasoline Station Pipe for Gas Station Build

PRODUCT PARAMETERS

Description

Overview of Whole Plastic Underground Petroleum Pipe for Petrol Gasoline Station Pipe for Gas Station Build

Whole Plastic Underground Petroleum Pipe for Petrol Gasoline Station Pipe for Gas Station Build is designed for efficient and secure gas transportation in residential, commercial, and industrial applications. Made from durable materials such as carbon steel, stainless steel, or PE polyethylene, our gas pipes ensure leak-proof performance and long-term reliability. Whether for natural gas, propane, or other fuel gases, our products meet strict industry standards for safety and efficiency.

Features of Whole Plastic Underground Petroleum Pipe for Petrol Gasoline Station Pipe for Gas Station Build

Corrosion-Resistant – Engineered to withstand harsh environments and prevent leaks.

High Pressure and Temperature Tolerance – Suitable for demanding gas distribution systems.

Lightweight and Flexible PE Pipes – Easy to install with excellent durability.

Leak-Proof Joints – Precision welding and threading for secure connections.

Compliant with Safety Standards – Certified for reliable performance in gas applications.

(Whole Plastic Underground Petroleum Pipe for Petrol Gasoline Station Pipe for Gas Station Build)

Specifications of Whole Plastic Underground Petroleum Pipe for Petrol Gasoline Station Pipe for Gas Station Build

These entire plastic below ground oil pipelines are constructed for gas filling station. They bring fuel securely underground. The pipes are made from solid polyethylene plastic. This material withstands rust well. Metal pipes rust with time. Plastic pipelines do not rust. They last much longer underground.

The pipe wall surfaces are thick. They handle high pressure from fuel pumps. Heavy vehicles drive over the ground over. The pipelines stay solid. They do not crack easily. The plastic is adaptable also. It flexes somewhat without breaking. This helps during setup. Ground motion happens. The pipe adapts.

Fuel is severe. These pipelines stand up to chemical attack. Petroleum and diesel won’t harm the plastic. The material stops leakages. It is nonporous. Fuel stays inside the pipe. Groundwater remains outside. This safeguards the atmosphere. Safety is important.

The pipes fulfill strict industry standards. They are certified safe for petroleum products. Fire security ratings are high. The pipelines have a smooth inside wall surface. Fuel moves quickly. Much less friction suggests far better pump efficiency. Clogs are unlikely.

Setup is straightforward. The plastic pipelines are light-weight. Employees handle them easily. Sections collaborate firmly. Heat combination creates leak-proof seals. The pipelines need little upkeep underground. They function reliably for years. Sunshine breaks down materials. These pipes are hidden. They prevent UV damage. Pick the right dimension for your terminal’s flow demands. Usual diameters are offered. Pressure ratings match station needs. These pipes are the functional choice for safe, sturdy gas lines.

(Whole Plastic Underground Petroleum Pipe for Petrol Gasoline Station Pipe for Gas Station Build)

Applications of Whole Plastic Underground Petroleum Pipe for Petrol Gasoline Station Pipe for Gas Station Build

Gasoline station need trustworthy pipes below ground to relocate fuel securely. Plastic pipelines made from difficult polyethylene are now the leading selection. These pipes stand up to deterioration well. They last a lot longer than old steel pipes. Gas and soil chemicals do not harm them. This suggests less leakages and less opportunity of pollution. That’s important for safeguarding the setting around the terminal.

Installment is less complex also. Plastic pipelines are much lighter than steel. Employees can handle them quickly. They connect quickly making use of heat fusion. This makes a seamless, solid joint. There are no powerlessness like threaded connections. The entire system becomes one solid item. This lowers setup time and labor costs significantly.

Safety is a significant advantage. Plastic pipes don’t trigger. They are safer near electrical lines or during digging work. Their flexibility helps them manage ground activity. They will not crack quickly if the soil changes. This stops harmful fuel leaks underground. Leakages are bad for the atmosphere and very expensive to deal with.

Making use of these plastic pipelines conserves money in time. Their lengthy life implies less regular replacement. Low maintenance cuts sets you back even more. You stay clear of the continuous repairs required with corroding steel pipelines. The first financial investment pays off for years. Gasoline station building contractors and proprietors get a dependable, affordable service. They make sure gasoline moves safely from tank to the pumps each day. This reliability is important for smooth station procedure.

Packing and Shipment

Depends on the products and qty,we could make the packing of coiling,rolls,bundle packing,crates or boxes,etc.

Shipment:By sea,railway,by air or as customer’s request.

Company Profile

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding HDPE Pipe Fitting, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net

Payment Terms

T/T,L/C at sight,Western Union & Paypal,etc.

5 FAQs of Whole Plastic Underground Petroleum Pipe for Petrol Gasoline Station Pipe for Gas Station Build

Underground Plastic Fuel Pipes for Gas Stations: Key Questions

What material are these pipes?

These pipes are made from special plastic. This plastic is designed for carrying petrol and gasoline underground. It resists the fuel’s chemicals. It prevents rust and corrosion completely.

How are these pipes installed?

Workers bury the pipes deep underground. This depth follows local safety rules. It protects the pipe from surface damage. Proper installation is vital for long-term safety and function.

Why choose plastic over metal?

Plastic pipes offer major advantages. They won’t corrode like metal pipes can. This corrosion resistance prevents leaks. It means the pipes last much longer underground. Plastic is also lighter and easier to handle during installation.

How do these pipes prevent leaks?

The pipe material itself is very strong and leak-proof. Systems also use continuous monitoring. Sensors track pressure along the pipe. Any pressure drop signals a possible leak. This allows for immediate action.

Are these pipes certified?

Yes. These pipes meet strict industry rules. They pass demanding safety tests. They are certified for underground fuel transport. Always check the specific certifications for your project location.

(Whole Plastic Underground Petroleum Pipe for Petrol Gasoline Station Pipe for Gas Station Build)

REQUEST A QUOTE

RELATED PRODUCTS

ASTM A106/A53 Gr. B API 5L Gr. B A179/A192/API 5CT J55/K55/N80 Carbon Seamless Steel Pipe Oil 6m 12m Certified API GS Tisi Emt

High Quality Stainless Steel Gas Pipes Stainless Steel Flexible Pipe

Available ASTM A53 Galvanized Steel Pipe For High Frequency Welding Of Oil Pipelines Galvanized Welded Pipe Greenhouse Pipe

Cold Drawn Carbon Steel Gas Pipe GB API ASTM A106 Sch80 Seamless API 5L/5DP ASTM A53-2007 GB 5310-1995 JIS Certified Length 12m

Sch40 Thick Wall Carbon Steel Seamless Pipes

High Quality ASTM A36 API 5L X42 X52 X56 X60 Steel Pipe ERW Welded Spiral Carbon Steel Pipe Used for Gas and Oil Pipeline

- Email: sales@pipesandfittings.net

- WeChat: +86 18337900677