LUOYANG DATANG ENERGY TECH CO.,LTD

Oxygen Gas Cylinder Valve CGA Cylinder Valve Industry Gas Cylinders Valve Whole

PRODUCT PARAMETERS

Description

Overview of Oxygen Gas Cylinder Valve CGA Cylinder Valve Industry Gas Cylinders Valve Whole

Oxygen Gas Cylinder Valve CGA Cylinder Valve Industry Gas Cylinders Valve Whole is essential components in gas supply systems, used to control the flow and pressure of gas in pipelines. They play a critical role in ensuring safety, efficiency, and reliability in residential, commercial, and industrial applications. Whether for natural gas, propane, or other gaseous fuels, our high-quality gas valves offer precise regulation and durable performance under varying conditions.

Features of Oxygen Gas Cylinder Valve CGA Cylinder Valve Industry Gas Cylinders Valve Whole

High durability and corrosion resistance materials

Precision engineering for accurate gas flow control

Safe and leak-proof design for reliable operation

Easy installation and maintenance

Available in various sizes and types to suit different applications

(Oxygen Gas Cylinder Valve CGA Cylinder Valve Industry Gas Cylinders Valve Whole)

Specifications of Oxygen Gas Cylinder Valve CGA Cylinder Valve Industry Gas Cylinders Valve Whole

Here are the specs for oxygen gas cylinder valves, CGA style. These valves control gas flow from high-pressure cylinders. They are built tough for oxygen service. Only trained people should handle them.

The valve body is solid brass. Brass resists sparks. This is critical for oxygen. Oxygen makes fires much worse. The valve stem is also brass or sometimes stainless steel. It turns smoothly to open or close the gas flow. A durable plastic handwheel is usually attached. The handwheel is color-coded green for oxygen.

The valve uses a CGA 540 connection. This is the standard inlet thread for oxygen cylinders in the US. It ensures the right regulator attaches securely. The outlet is typically male threads. It connects directly to the regulator or hose. The valve must seal perfectly when closed. Zero leaks are mandatory. A damaged valve is unsafe.

Working pressure is high. These valves handle up to 3,000 PSI. They must withstand this pressure constantly. Burst pressure is much higher for safety. Valves are tested rigorously. Each valve undergoes pressure tests before leaving the factory. Leak tests are also performed. Safety is the top priority.

A packing seal surrounds the stem. It prevents gas from escaping around the turning part. This seal needs occasional checking. Proper lubrication is vital. Only oxygen-compatible lubricant can be used. Regular grease can ignite with oxygen.

Installation requires care. The valve threads into the cylinder neck port. Hand-tighten it first. Then use a wrench for the final turns. Do not overtighten. Overtightening can damage threads. Damaged threads cause leaks. Always check for leaks after installing. Use a leak detection solution. Listen for hissing sounds. Never use a flame to check.

Valves must be kept clean. Dirt or oil inside an oxygen valve is extremely dangerous. Contamination can cause a violent fire. Always use clean tools. Wear clean gloves. Protect open ports with caps when not in use. Store valves properly. Keep them in a dry, clean place. Follow all safety rules for oxygen equipment.

(Oxygen Gas Cylinder Valve CGA Cylinder Valve Industry Gas Cylinders Valve Whole)

Applications of Oxygen Gas Cylinder Valve CGA Cylinder Valve Industry Gas Cylinders Valve Whole

Oxygen gas cylinder valves are essential hardware. They control the flow of oxygen out of high-pressure cylinders. Safety is the most important job. These valves stop leaks. Leaks are dangerous near sparks or flames. A good seal keeps oxygen inside until needed.

Workers turn the valve handle to open or shut the flow. This controls the oxygen release. Medical settings rely heavily on these valves. Hospitals use them for patient breathing support. Emergency oxygen therapy needs a dependable valve. Dentists and clinics use them too. Welding and metal cutting shops depend on oxygen valves. The valves feed oxygen to torches for hot work. Factories use them in various metal processes.

Laboratories need precise oxygen control for experiments. Research facilities use these valves daily. Aerospace and manufacturing plants use large oxygen supplies. Reliable valves are critical there. The valve connects directly to the cylinder. It must handle very high pressure safely. Correct installation is vital. Only trained people should handle cylinder valves.

Regular inspection matters. Look for damage or wear. Proper maintenance keeps valves working right. Valves must match the cylinder type and gas. CGA connections ensure the right fit. Using the wrong valve is unsafe. Oxygen service demands clean, contaminant-free valves. Oil or grease near oxygen can cause fire. Dedicated oxygen valves prevent this risk. They are made for pure oxygen only.

These valves are found everywhere oxygen is stored and used. They are a simple but vital link. Their job is always safety and control.

Packing and Shipment

Depends on the products and qty,we could make the packing of coiling,rolls,bundle packing,crates or boxes,etc.

Shipment:By sea,railway,by air or as customer’s request.

Company Profile

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding HDPE Pipe Fitting, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net

Payment Terms

T/T,L/C at sight,Western Union & Paypal,etc.

5 FAQs of Oxygen Gas Cylinder Valve CGA Cylinder Valve Industry Gas Cylinders Valve Whole

This valve controls oxygen flow from gas cylinders. It connects securely to the cylinder top. You turn the handwheel to open or close it. This lets gas out safely when needed. It also seals the cylinder tightly during storage or transport. This prevents leaks and waste.

Safety is critical. Oxygen feeds fires easily. The valve must prevent sparks and leaks. Special seals work with high-pressure oxygen. They won’t catch fire. The valve body is usually brass. Brass doesn’t spark. This reduces ignition risk significantly.

Brass is the common material. It handles high pressure well. Brass resists corrosion from oxygen. It’s also durable. Steel valves exist but need special approval. Oxygen makes some materials burn violently. Wrong materials cause serious accidents. Always use valves designed for oxygen.

CGA fittings are key. CGA means Compressed Gas Association. This group sets connection standards. Different gases need different CGA fittings. This prevents wrong connections. Oxygen cylinders usually use CGA 540. Your valve must match this fitting. Check your cylinder connection type first. Using the wrong CGA fitting is dangerous.

Regular checks are necessary. Look for leaks often. Use leak detection solution. Watch for damaged parts. Listen for hissing sounds. Replace worn seals immediately. Keep the valve clean. Dirt or oil near oxygen can ignite. Don’t force the handwheel. Lubricate only with approved oxygen-safe grease. Follow the manufacturer’s inspection schedule closely.

(Oxygen Gas Cylinder Valve CGA Cylinder Valve Industry Gas Cylinders Valve Whole)

REQUEST A QUOTE

RELATED PRODUCTS

Desktop Gas Valve

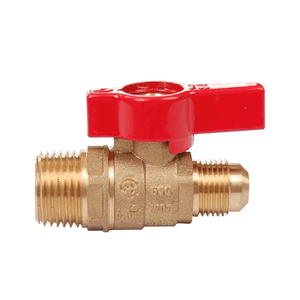

Customizable Oem Manual Gas Ball Valve Low and High Temperature Shutoff Gas Valve for General Use Forged Brass Ball Valve

Factory Direct Supply Zinc/Aluminum Gas Valve for Home Cooking Gas Use – Mainly for Bolivia Market

Gas Control Safety Valve For Stove Cooktop

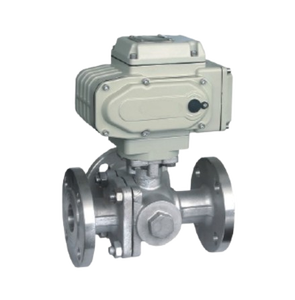

Professional High Pressure Gas Station Valve with Flange Shutoff Gas Valve for Gas Manifold Shutoff Valves

Industrial Metal Aerosol Gas Valve Portable Butane Gas Stove Valve for Chemical Use

- Email: sales@pipesandfittings.net

- WeChat: +86 18337900677