LUOYANG DATANG ENERGY TECH CO.,LTD

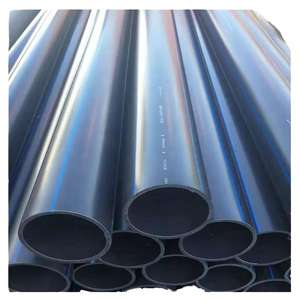

355mm HDPE Pipe PE100 High Density Polyethylene Dredging Float Pipes

PRODUCT PARAMETERS

Description

Introduction of 355mm HDPE Pipe PE100 High Density Polyethylene Dredging Float Pipes

High Density Polyethylene Pipe (PE Pipe) is a durable and flexible thermoplastic piping solution widely used in industrial, municipal, agricultural, and mining applications. Known for its excellent chemical resistance, high impact strength, and long service life, PE pipes are ideal for transporting water, gases, and other fluids under varying pressure conditions.

Key Features of 355mm HDPE Pipe PE100 High Density Polyethylene Dredging Float Pipes

Corrosion & Chemical Resistance

Resistant to rust, scale, and most chemicals, making it suitable for aggressive environments.

Lightweight & Flexible

Easy to transport and install due to low weight; flexibility allows bending without joints in certain applications.

High Impact Strength

Withstands extreme weather conditions and physical stress, reducing breakage risks.

Leak-Free Joints

Heat-fused joints create seamless connections, minimizing leakage risks.

Long Service Life

UV-resistant and abrasion-proof, with a lifespan exceeding 50 years under proper conditions.

Smooth Inner Surface

Reduces friction loss, improving flow efficiency and lowering energy costs.

Eco-Friendly

Non-toxic, recyclable, and compliant with drinking water safety standards.

Cost-Effective

Lower installation and maintenance costs compared to traditional materials (e.g., metal, concrete).

(355mm HDPE Pipe PE100 High Density Polyethylene Dredging Float Pipes)

Specifications of 355mm HDPE Pipe PE100 High Density Polyethylene Dredging Float Pipes

Below are the specifications for 355mm HDPE Pipe PE100 High Density Polyethylene Dredging Float Pipes. This pipe is made from PE100 grade high-density polyethylene. PE100 is a top-tier product known for its strength and durability. The pipe size is 355 millimeters. It is developed especially for demanding dredging operations.

The wall density is 28.7 millimeters. This thickness supplies the necessary architectural stability. It guarantees the pipeline can take care of the high stress found in dredging job. Buoyancy is a vital function. The pipeline floats easily on water. This makes it best for delivering dredged slurry over long distances. You do not need extra flotation devices.

PE100 product provides outstanding resistance. It won’t corrosion or wear away like metal pipelines. It manages chemicals well. It likewise stands up to sunshine and UV rays without deteriorating. The smooth inner surface is important. It allows slurry action quickly through the pipe. This reduces friction. It likewise reduces the energy required for pumping. The pipeline relocates smoothly with water.

The pipe is very tough. It withstands influence damages well. It takes care of abrasion from sand and crushed rock successfully. This implies it lasts a long period of time also in rough problems. Its lightweight is a big benefit. Employees can install it quicker. They can handle it less complicated than heavier steel pipelines. This conserves time and money on projects.

Jointing is uncomplicated. Areas connect accurately utilizing electrofusion or butt welding. These techniques develop strong, leak-free joints. The pipe is flexible. It can flex slightly to adhere to the path needed on the dredging site. This flexibility aids throughout installment. It likewise assists the pipe take care of changing water currents.

(355mm HDPE Pipe PE100 High Density Polyethylene Dredging Float Pipes)

Applications of 355mm HDPE Pipe PE100 High Density Polyethylene Dredging Float Pipes

These 355mm HDPE PE100 pipelines are necessary for digging up projects. They drift pipes lugging mud, sand, and water. Their work is maintaining the pipe secure on the water surface area. This makes dredging work a lot easier.

HDPE material is difficult. It withstands saltwater, chemicals, and sunshine damages. Steel pipelines rust swiftly. These plastic pipes last a lot longer. They conserve money over time. Maintenance is reduced. You do not require continuous repairs.

These pipes connect conveniently. Workers join them fast on website. This quickens setup. Time is essential on digging up jobs. Quick arrangement implies reduced costs. The pipes are additionally light. Each pipe evaluates concerning 100kg. Handling them is straightforward. Heavy tools isn’t always needed.

Buoyancy is essential. These pipelines have high buoyancy. They sustain the heavy dredge tube and product within. This quits the pipe from sinking. Less assistance pontoons are essential. This reduces equipment needs. It likewise lowers the task impact.

The pipes are versatile. They deal with waves and currents well. They flex without damaging. This versatility protects against fractures. It makes certain the dredge line stays intact. Downtime is decreased.

HDPE is non-toxic. It doesn’t hurt aquatic life. This matters for ecological regulations. Projects stay compliant. Operators prevent fines. The product is likewise recyclable. It sustains eco-friendly methods.

These pipelines work in lots of water problems. They are made use of in rivers, lakes, ports, and seaside areas. They take care of superficial and deeper water. Convenience is a significant advantage. One pipe kind fits numerous tasks.

Toughness is shown. HDPE PE100 holds up against impact. Rocks and particles trigger little damage. The pipe keeps operating. Project delays are much less likely. Integrity is high.

Expense effectiveness is clear. Reduced initial price than steel. Lower lifetime cost also. Lowered maintenance, longer life, and much easier taking care of accumulate. They provide genuine financial savings. Operators get great value.

Packing and Shipment

Depends on the products and qty,we could make the packing of coiling,rolls,bundle packing,crates or boxes,etc.

Shipment:By sea,railway,by air or as customer’s request.

Company Profile

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding HDPE Pipe Fitting, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net

Payment Terms

T/T,L/C at sight,Western Union & Paypal,etc.

5 FAQs of 355mm HDPE Pipe PE100 High Density Polyethylene Dredging Float Pipes

What are 355mm HDPE PE100 float pipes?

These pipes are large plastic tubes, 355mm wide. They are made from PE100 grade HDPE. This material is strong, flexible, and resists chemicals. The pipes include built-in buoyancy chambers. They float on water, used mainly for dredging operations to move sand, silt, or water.

Why use HDPE pipes for dredging?

HDPE pipes are perfect for dredging. They float naturally, needing fewer pontoons. They resist rust and corrosion from saltwater or chemicals. HDPE handles rough treatment well, including bumps and scrapes. The material is flexible, surviving bending without breaking. These pipes last a long time in tough conditions.

How do you connect these dredging pipes?

Connecting these pipes is straightforward. Workers use flanges or electrofusion couplings. Flanges bolt sections together securely. Electrofusion melts the pipe ends, fusing them into one solid piece. Both methods create strong, leak-proof joints. This ensures reliable flow during dredging projects.

What buoyancy do these pipes provide?

The 355mm HDPE PE100 pipes have integrated air chambers. This design gives them permanent positive buoyancy. They float high on the water surface. The buoyancy supports the pipe weight and the material flowing inside. This reduces the need for extra floating devices. It simplifies the dredging setup.

How long do these HDPE float pipes last?

These pipes offer exceptional service life. HDPE PE100 resists environmental damage like UV rays and chemicals. It withstands abrasion from sediments. Properly installed and used, these pipes can function reliably for decades. Their long lifespan lowers replacement costs. This makes them a cost-effective solution for dredging.

(355mm HDPE Pipe PE100 High Density Polyethylene Dredging Float Pipes)

REQUEST A QUOTE

RELATED PRODUCTS

High Density Polyethylene Tube HDPE Pipe

High Pressure HDPE Pipe for Water Supply Irrigation Agriculture Flexible Underground Drainage Roll-Industrial Construction

Hdpe Perforated Drainage Pipe 100mm 110mm Sdr11 Dn150 160mm 200mm 250mm 280mm Pe Water Pipe For Irrigation

High Density Polyethylene Tube HDPE Pipes PE Water Pipe For Supply And Drainage

Pn10 Pn16 HDPE Tube Large Diameter 110mm-280mm PE100 Plastic Tubing For Garden Hotel High-Density Polyethylene (HDPE) Pipe

High Quality Plastic Pipe 5 6 8 10 Inch Diameter Pvc Water Pipe 300mm 600mm Water Upvc Pipe Size

- Email: sales@pipesandfittings.net

- WeChat: +86 18337900677