LUOYANG DATANG ENERGY TECH CO.,LTD

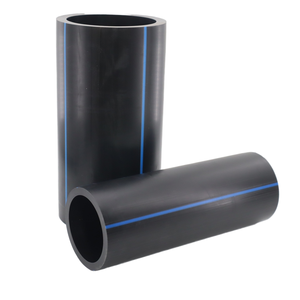

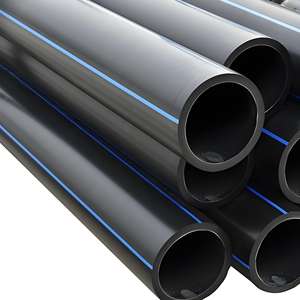

Blue Stripe Hdpe Pipe 500 Mm SDR11 PN16 PE Pipe High Wear Resistant Pe 100 Hdpe Pipe For Dredging And Mining Industry

PRODUCT PARAMETERS

Description

Introduction of Blue Stripe Hdpe Pipe 500 Mm SDR11 PN16 PE Pipe High Wear Resistant Pe 100 Hdpe Pipe For Dredging And Mining Industry

High Density Polyethylene Pipe (PE Pipe) is a durable and flexible thermoplastic piping solution widely used in industrial, municipal, agricultural, and mining applications. Known for its excellent chemical resistance, high impact strength, and long service life, PE pipes are ideal for transporting water, gases, and other fluids under varying pressure conditions.

Key Features of Blue Stripe Hdpe Pipe 500 Mm SDR11 PN16 PE Pipe High Wear Resistant Pe 100 Hdpe Pipe For Dredging And Mining Industry

Corrosion & Chemical Resistance

Resistant to rust, scale, and most chemicals, making it suitable for aggressive environments.

Lightweight & Flexible

Easy to transport and install due to low weight; flexibility allows bending without joints in certain applications.

High Impact Strength

Withstands extreme weather conditions and physical stress, reducing breakage risks.

Leak-Free Joints

Heat-fused joints create seamless connections, minimizing leakage risks.

Long Service Life

UV-resistant and abrasion-proof, with a lifespan exceeding 50 years under proper conditions.

Smooth Inner Surface

Reduces friction loss, improving flow efficiency and lowering energy costs.

Eco-Friendly

Non-toxic, recyclable, and compliant with drinking water safety standards.

Cost-Effective

Lower installation and maintenance costs compared to traditional materials (e.g., metal, concrete).

(Blue Stripe Hdpe Pipe 500 Mm SDR11 PN16 PE Pipe High Wear Resistant Pe 100 Hdpe Pipe For Dredging And Mining Industry)

Specifications of Blue Stripe Hdpe Pipe 500 Mm SDR11 PN16 PE Pipe High Wear Resistant Pe 100 Hdpe Pipe For Dredging And Mining Industry

This Blue Red Stripe HDPE Pipe is developed difficult for demanding jobs. It measures 500 millimeters in size. The pipeline uses SDR11 dimensioning. This SDR11 ranking implies a details wall density relative to its size. The pipeline lugs a PN16 stress score. This PN16 rating verifies it takes care of stress approximately 16 bar securely. The material is top-quality PE100 HDPE. PE100 is the greatest polyethylene type available.

The pipe excels in high-wear situations. Its PE100 building supplies superior resistance to abrasion. Abrasive materials scrape and use down minimal pipelines quickly. This pipeline withstands that continuous scraping far better. This wear resistance is critical for its main usages. It is made specifically for the dredging and mining markets.

Dredging includes relocating sand, silt, and crushed rock. These products are extremely abrasive. Mining operations transport slurries containing rocks and minerals. These slurries quickly break common pipelines. This HDPE pipe lasts a lot longer under these rough problems. It minimizes downtime and replacement expenses dramatically.

The blue red stripe along the pipeline is a vital attribute. It supplies clear aesthetic recognition. Workers easily acknowledge it as a high-pressure HDPE pipe. This quick recognition is essential on hectic worksites. It helps stop unintentional usage where it’s not suitable. The blue red stripe guarantees proper pipeline choice for the work.

This pipeline provides a reliable option for moving unpleasant solids. Its strength and toughness make it optimal for tough applications. It deals with the punishing environments discovered in dredging and mining effectively.

(Blue Stripe Hdpe Pipe 500 Mm SDR11 PN16 PE Pipe High Wear Resistant Pe 100 Hdpe Pipe For Dredging And Mining Industry)

Applications of Blue Stripe Hdpe Pipe 500 Mm SDR11 PN16 PE Pipe High Wear Resistant Pe 100 Hdpe Pipe For Dredging And Mining Industry

This Blue Stripe HDPE pipe measures 500 millimeters. It’s SDR11 rated. The pressure rating is PN16. It’s made from tough PE100 material. This pipe handles heavy wear exceptionally well. It’s perfect for demanding jobs in dredging and mining.

Mining operations push pipes hard. They move abrasive slurries like tailings and ore. They handle corrosive mine drainage water. They transport process water over rough ground. This HDPE pipe withstands the constant scraping from sand, gravel, and rocks inside it. Its surface resists getting worn down. This means the pipe lasts much longer. It saves money on replacements and downtime.

Dredging work is equally tough. Pipes suck up sand, silt, and mud from riverbeds or seabeds. This mixture is incredibly abrasive. It flows fast under high pressure. Standard pipes wear out quickly. This blue stripe HDPE pipe is built for it. Its special material fights the scouring effect. It maintains its strength and flow capacity over time. It keeps dredging projects moving efficiently.

The pipe’s smooth inside surface is a big plus. It lets thick slurries flow easily. Less friction means less energy is needed to pump materials. It also reduces the risk of blockages. This smoothness helps prevent material from sticking inside the pipe.

HDPE is naturally flexible. It can bend slightly without breaking. This is useful on uneven mining sites or floating dredge lines. It handles ground movement better than rigid pipes. It absorbs some shock and vibration.

Joining sections is straightforward using heat fusion. This creates a leak-proof seal as strong as the pipe itself. There are no weak points at the joints. This reliability is crucial for continuous operations. The pipe is also lightweight. This makes handling and installation faster and cheaper than metal pipes. It doesn’t rust or corrode like metal either. It stays strong in wet, salty, or chemically harsh environments common in these industries.

Packing and Shipment

Depends on the products and qty,we could make the packing of coiling,rolls,bundle packing,crates or boxes,etc.

Shipment:By sea,railway,by air or as customer’s request.

Company Profile

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding HDPE Pipe Fitting, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net

Payment Terms

T/T,L/C at sight,Western Union & Paypal,etc.

5 FAQs of Blue Stripe Hdpe Pipe 500 Mm SDR11 PN16 PE Pipe High Wear Resistant Pe 100 Hdpe Pipe For Dredging And Mining Industry

This Blue Stripe HDPE Pipe 500mm SDR11 PN16 is built tough for dredging and mining. Here are common questions answered:

What material is this pipe made from? It uses PE 100 HDPE. This material is very strong. It resists wear extremely well. It handles rough materials like sand and rocks without damage.

What do SDR11 and PN16 mean? SDR11 is the thickness rating. It means the pipe walls are thick for its size. PN16 is the pressure rating. It handles up to 16 bar pressure. This pipe is sturdy for heavy industrial jobs.

Why choose this pipe for dredging or mining? It fights abrasion better than metal pipes. Sand and gravel wear down metal fast. This HDPE pipe lasts much longer. It saves money on replacements. It cuts downtime too.

Is this pipe resistant to chemicals? Yes absolutely. Mining often uses harsh chemicals. This pipe won’t rust or corrode. It stays reliable in wet or chemical environments. It’s safe for long-term use.

How are these pipes connected? They use standard HDPE joining methods. Butt fusion is common. Electrofusion works too. These methods create strong seals. Leaks won’t happen. Installation is quick and secure.

(Blue Stripe Hdpe Pipe 500 Mm SDR11 PN16 PE Pipe High Wear Resistant Pe 100 Hdpe Pipe For Dredging And Mining Industry)

REQUEST A QUOTE

RELATED PRODUCTS

High Quality Plastic Pipe 5 6 8 10 Inch Diameter Pvc Water Pipe 300mm 600mm Water Upvc Pipe Size

Hdpe High Density Polyethylene Extrusion Molding HHM TR480AT Hdpe Granules Pipe Grade Virgin HDPE Plastic Raw Materials

HDPE Plastic Tubes PE Water Supply Pipe Drainage Irrigation Pipe

Irrigation Pipe System Garden Drip Water Timer Polyethylene HDPE Pipe s Pe100 Pe Hd Pipe Tube

Factory Direct 1.6MPa HDPE Pipe Welding Butt Fusion Plastic Tubes Water Supply Drainage Polyethylene Pipe

Pn10 Pn16 HDPE Tube Large Diameter 110mm-280mm PE100 Plastic Tubing For Garden Hotel High-Density Polyethylene (HDPE) Pipe

- Email: sales@pipesandfittings.net

- WeChat: +86 18337900677