LUOYANG DATANG ENERGY TECH CO.,LTD

Hdpe High Density Polyethylene Extrusion Molding HHM TR480AT Hdpe Granules Pipe Grade Virgin HDPE Plastic Raw Materials

PRODUCT PARAMETERS

Description

Introduction of Hdpe High Density Polyethylene Extrusion Molding HHM TR480AT Hdpe Granules Pipe Grade Virgin HDPE Plastic Raw Materials

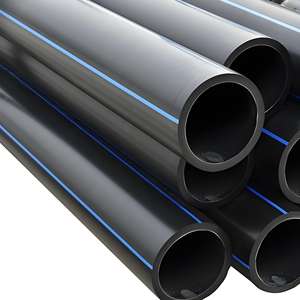

High Density Polyethylene Pipe (PE Pipe) is a durable and flexible thermoplastic piping solution widely used in industrial, municipal, agricultural, and mining applications. Known for its excellent chemical resistance, high impact strength, and long service life, PE pipes are ideal for transporting water, gases, and other fluids under varying pressure conditions.

Key Features of Hdpe High Density Polyethylene Extrusion Molding HHM TR480AT Hdpe Granules Pipe Grade Virgin HDPE Plastic Raw Materials

Corrosion & Chemical Resistance

Resistant to rust, scale, and most chemicals, making it suitable for aggressive environments.

Lightweight & Flexible

Easy to transport and install due to low weight; flexibility allows bending without joints in certain applications.

High Impact Strength

Withstands extreme weather conditions and physical stress, reducing breakage risks.

Leak-Free Joints

Heat-fused joints create seamless connections, minimizing leakage risks.

Long Service Life

UV-resistant and abrasion-proof, with a lifespan exceeding 50 years under proper conditions.

Smooth Inner Surface

Reduces friction loss, improving flow efficiency and lowering energy costs.

Eco-Friendly

Non-toxic, recyclable, and compliant with drinking water safety standards.

Cost-Effective

Lower installation and maintenance costs compared to traditional materials (e.g., metal, concrete).

(Hdpe High Density Polyethylene Extrusion Molding HHM TR480AT Hdpe Granules Pipe Grade Virgin HDPE Plastic Raw Materials)

Specifications of Hdpe High Density Polyethylene Extrusion Molding HHM TR480AT Hdpe Granules Pipe Grade Virgin HDPE Plastic Raw Materials

HHM TR480AT HDPE granules supply top notch virgin product perfect for pipeline extrusion. This high-density polyethylene supplies superb buildings for demanding pipeline applications. It offers strong stiffness and high thickness. This makes certain pipes stand up to stress and deformation well. The material reveals impressive strength. It manages impacts effectively even in cool conditions. This durability is essential for underground pipes.

Chemical resistance is a vital attribute. HDPE TR480AT stands up to many acids, antacid, and solvents. This avoids deterioration and expands pipe life expectancy considerably. It additionally resists ecological tension fracturing fantastically. This dependability is important for long-lasting facilities tasks. The product satisfies rigorous ISO 4427 criteria for polyethylene pipe compounds. You obtain constant, certified performance.

Processing HHM TR480AT is straightforward. Its properties are tailored for smooth extrusion molding. The granules melt equally and move well. This permits effective manufacturing of pipes with consistent wall surface thickness. It decreases processing issues like thaw crack. You achieve high result prices and constant product quality. The product is pure virgin material. It consists of no recycled content. This assures foreseeable homes and avoids contamination dangers.

HDPE TR480AT pipelines are durable and lightweight. They last years with very little upkeep. The material uses great resistance to UV light. This is important for exposed applications. Its reduced moisture absorption maintains performance secure. These pipelines are ideal for supply of water, sewage systems, and industrial conduits. They offer a cost-effective service.

(Hdpe High Density Polyethylene Extrusion Molding HHM TR480AT Hdpe Granules Pipe Grade Virgin HDPE Plastic Raw Materials)

Applications of Hdpe High Density Polyethylene Extrusion Molding HHM TR480AT Hdpe Granules Pipe Grade Virgin HDPE Plastic Raw Materials

This HDPE material is created extrusion molding. Individuals use it to make pipelines and various other items. The quality is TR480AT. It’s virgin high-density polyethylene. That suggests it’s pure plastic, not reused. This provides it solid, trusted high qualities.

This HDPE granule is ideal for pipes. It produces pipes for alcohol consumption water. It also makes pipes for sewage systems. The material resists chemicals effectively. Water will not damage it. Dirt chemicals will not hurt it either. This keeps the pipes risk-free and resilient.

Gas pipelines are an additional large usage. This HDPE benefits natural gas lines. It likewise benefits gas systems. Safety is essential right here. This product meets rigorous criteria. It does not leak easily. It manages stress well. This makes it relied on for gas transportation.

Industrial applications are very important too. Manufacturing facilities use it for chemical transportation lines. Mines utilize it for slurry pipes. The material handles harsh things. It won’t corrode like metal. It endures hard atmospheres. This decreases substitute costs.

Ecological tasks utilize this HDPE. It lines landfills securely. It caps waste sites safely. The product quits leakages into dirt. It safeguards groundwater. Its strength lasts for years underground.

The material supplies crucial advantages. It’s very resilient. Water lines last a very long time. It flexes without breaking. This assists during installment. It will not fracture in winter. It deals with temperature modifications. It’s also lighter than metal pipes. This makes shipping more affordable. Installation is simpler as well.

Manufacturers like its handling ease. It melts efficiently in extruders. This offers constant pipeline wall surfaces. Quality control is less complex. It creates solid, reputable pipes. This saves time and material.

Packing and Shipment

Depends on the products and qty,we could make the packing of coiling,rolls,bundle packing,crates or boxes,etc.

Shipment:By sea,railway,by air or as customer’s request.

Company Profile

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding HDPE Pipe Fitting, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net

Payment Terms

T/T,L/C at sight,Western Union & Paypal,etc.

5 FAQs of Hdpe High Density Polyethylene Extrusion Molding HHM TR480AT Hdpe Granules Pipe Grade Virgin HDPE Plastic Raw Materials

Here are five common questions about Hdpe High Density Polyethylene Extrusion Molding HHM TR480AT Hdpe Granules Pipe Grade Virgin HDPE Plastic Raw Materials:

What is TR480AT HDPE best used for?

TR480AT HDPE granules are made for pipe extrusion. This material creates strong, durable pipes. It handles water pressure well. It resists chemicals. It lasts long underground. You get reliable pipes for water supply, drainage, and irrigation systems.

What makes TR480AT good for pipe extrusion?

This grade flows smoothly in extruders. It melts evenly. This gives consistent pipe walls. It has high stiffness. This keeps pipe shape under pressure. It offers excellent resistance to cracks. This is key for long-term underground use.

What temperature should I use for extrusion?

Process TR480AT between 180°C and 220°C. This is the melt temperature range. Find the best setting for your machine. Watch barrel and die temperatures closely. Consistent heat prevents problems. It ensures good pipe quality.

Does this material need drying before use?

Yes. Dry TR480AT granules first. Moisture causes defects. Use a dehumidifying dryer. Keep the temperature around 80°C. Dry for 2 to 3 hours. Proper drying prevents bubbles and surface flaws in the pipe.

Is TR480AT certified for safe water contact?

Yes. This virgin HDPE grade meets standards for potable water. It passes relevant health and safety tests. It contains no recycled content. It is safe for drinking water pipes. Check the specific certificates for your region.

(Hdpe High Density Polyethylene Extrusion Molding HHM TR480AT Hdpe Granules Pipe Grade Virgin HDPE Plastic Raw Materials)

REQUEST A QUOTE

RELATED PRODUCTS

High-quality PE Pipes PN12, PN16, SDR11, SDR21, PE100, 110 Mm, 150 Mm, 250 Mm, 900 Mm, DN1000 Large Diameter PE Pipes

High Quality Plastic Pipe 5 6 8 10 Inch Diameter Pvc Water Pipe 300mm 600mm Water Upvc Pipe Size

Pn6~16 High Density Polyethylene HDPE Pipe for Water Supply/Gas/Mining/Agriculture Irrigation/Drainage

Pn6~16 High Density Polyethylene HDPE Pipe for Water Supply/Gas/Mining/Agriculture Irrigation/Drainage

High-Density Polyethylene (PE) Black Pipe for Gas Line Use

PE100 Polyethylene Gas Pipe For LNG Project

- Email: sales@pipesandfittings.net

- WeChat: +86 18337900677