LUOYANG DATANG ENERGY TECH CO.,LTD

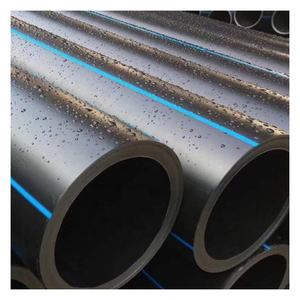

HDPE PE100 High Density Polyethylene Floating Water Mud Slurry Sand Gas Oil Dredging Dredge Dredger Mining Supply Plastic Pipe

PRODUCT PARAMETERS

Description

Introduction of HDPE PE100 High Density Polyethylene Floating Water Mud Slurry Sand Gas Oil Dredging Dredge Dredger Mining Supply Plastic Pipe

High Density Polyethylene Pipe (PE Pipe) is a durable and flexible thermoplastic piping solution widely used in industrial, municipal, agricultural, and mining applications. Known for its excellent chemical resistance, high impact strength, and long service life, PE pipes are ideal for transporting water, gases, and other fluids under varying pressure conditions.

Key Features of HDPE PE100 High Density Polyethylene Floating Water Mud Slurry Sand Gas Oil Dredging Dredge Dredger Mining Supply Plastic Pipe

Corrosion & Chemical Resistance

Resistant to rust, scale, and most chemicals, making it suitable for aggressive environments.

Lightweight & Flexible

Easy to transport and install due to low weight; flexibility allows bending without joints in certain applications.

High Impact Strength

Withstands extreme weather conditions and physical stress, reducing breakage risks.

Leak-Free Joints

Heat-fused joints create seamless connections, minimizing leakage risks.

Long Service Life

UV-resistant and abrasion-proof, with a lifespan exceeding 50 years under proper conditions.

Smooth Inner Surface

Reduces friction loss, improving flow efficiency and lowering energy costs.

Eco-Friendly

Non-toxic, recyclable, and compliant with drinking water safety standards.

Cost-Effective

Lower installation and maintenance costs compared to traditional materials (e.g., metal, concrete).

(HDPE PE100 High Density Polyethylene Floating Water Mud Slurry Sand Gas Oil Dredging Dredge Dredger Mining Supply Plastic Pipe)

Specifications of HDPE PE100 High Density Polyethylene Floating Water Mud Slurry Sand Gas Oil Dredging Dredge Dredger Mining Supply Plastic Pipe

HDPE PE100 pipelines use leading efficiency for tough jobs in dredging and mining. This high-density polyethylene material manages water, mud, slurry, sand, gas, and oil successfully. It functions perfectly for floating dredge operations, extracting supply lines, and other durable usages.

These pipelines resist deterioration completely. Harsh chemicals, salty water, and rough products cause no damage. This resistance suggests lengthy service life also in rough atmospheres.

PE100 material gives excellent flexibility. The pipelines bend easily without damaging. This adaptability allows basic installment around challenges. It also handles ground activity securely.

HDPE pipes remain lightweight. Workers move and link them with marginal initiative. This decreases labor costs and speeds up task timelines.

Pressure handling is solid. HDPE PE100 pipelines take care of high-pressure flows accurately. They match pumping applications like sand transfer or slurry elimination perfectly.

Joint stability is safe and secure. Heat-fused joints produce watertight seals more powerful than the pipe itself. This avoids pricey leakages throughout operation.

Temperature level resistance is wide. These pipes perform in severe cold and warm. They remain useful from -40 ° C to

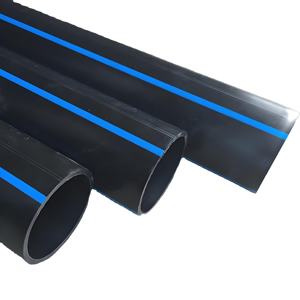

60 ° C. Requirement dimensions range from 20mm to 1600mm diameter. Wall surface densities vary to match stress demands. Personalized lengths and installations are readily available.

UV resistance is integrated. Black HDPE pipelines consist of carbon black for sun defense. They stand up to continuous exterior direct exposure without deteriorating.

Buoyancy functions help drifting arrangements. The material floats naturally on water. This simplifies dredging pipe arrangements.

Environmental security is ensured. HDPE pipes release no toxic substances. They carry drinking water safely. Recyclability supports eco-friendly projects.

Longevity cuts replacement prices. The material stands up to effects and wear. Maintenance needs stay low over years of usage.

Authorizations meet international requirements. Qualifications include ISO 4427, EN 12201, and ASTM F714. Quality assurance makes certain uniformity.

Price efficiency originates from durability. Reduced life time expenditures defeat metal or concrete alternatives.

(HDPE PE100 High Density Polyethylene Floating Water Mud Slurry Sand Gas Oil Dredging Dredge Dredger Mining Supply Plastic Pipe)

Applications of HDPE PE100 High Density Polyethylene Floating Water Mud Slurry Sand Gas Oil Dredging Dredge Dredger Mining Supply Plastic Pipe

HDPE PE100 pipelines are difficult plastic tubes. They handle harsh jobs well. Digging up usages these pipelines to relocate mud and sand. Mining procedures depend on them for slurry and tailings transportation. The material stands up to wear from abrasive bits. This saves money on substitutes.

Water monitoring gain from these pipes. They bring drinking water securely. Their smooth interior avoids build-up. This keeps water circulation efficient. Drifting systems use HDPE pipelines as well. They link pontoons and digging up tools. The pipes float naturally. This simplifies setup on water.

Oil and gas applications require dependable transfer. HDPE pipelines help low-pressure fuel lines. They stand up to rust from chemicals. This prevents leaks and environmental injury. Industrial plants pick these pipelines for slurry handling. Manufacturing facilities move waste materials with them daily.

Setup is simple. Workers sign up with sections with warmth blend. This develops smooth links. No leakages take place at welded joints. The pipes flex somewhat without breaking. They adjust to uneven ground. This reduces fitting prices.

HDPE PE100 stands up to severe temperatures. Hot sunlight or freezing cold will not split them. Deep sea atmospheres do not trigger corrosion. These pipelines last decades outdoors. Maintenance demands are minimal. Simply check for surface damages sometimes.

Cost performance issues for huge jobs. These pipes offer long service life. Their light-weight nature cuts shipping costs. Handling needs much less equipment. Quick installment saves labor time. Substitute periods are long. This reduces overall possession costs.

Packing and Shipment

Depends on the products and qty,we could make the packing of coiling,rolls,bundle packing,crates or boxes,etc.

Shipment:By sea,railway,by air or as customer’s request.

Company Profile

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding HDPE Pipe Fitting, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net

Payment Terms

T/T,L/C at sight,Western Union & Paypal,etc.

5 FAQs of HDPE PE100 High Density Polyethylene Floating Water Mud Slurry Sand Gas Oil Dredging Dredge Dredger Mining Supply Plastic Pipe

HDPE PE100 Floating Pipes: Your Dredging & Mining Solution FAQs

What makes HDPE pipes better than metal for dredging?

HDPE pipes float naturally. This buoyancy is a big advantage. Metal pipes sink and need extra floats. HDPE also handles corrosive materials well. Salt water, slurry, and chemicals don’t damage it like metal. Metal rusts and corrodes over time. HDPE avoids this problem completely.

Why is PE100 material important?

PE100 is a top grade of HDPE plastic. It means high density polyethylene with a minimum required strength rating. This rating guarantees the pipe can handle high pressures. Dredging pumps create strong internal pressure. PE100 pipes manage this pressure safely for a long time.

Can HDPE pipe handle abrasive sand and slurry?

Yes, HDPE handles abrasive materials very well. Sand, mud, and gritty slurries wear down metal pipes fast. The smooth inner surface of HDPE pipe reduces friction. Material flows easier. Less friction means less wear. This gives the pipe a much longer working life in tough conditions.

How do the pipes actually float?

The pipes themselves are buoyant. HDPE plastic is lighter than water. We design the pipes with air inside. This trapped air adds extra buoyancy. The pipes stay on the water surface easily. You connect sections together. The whole pipeline floats without needing lots of separate buoyancy aids.

How do you connect the floating pipe sections?

Two main methods work reliably. Butt fusion welding melts the pipe ends together. This creates a seamless, leak-proof joint as strong as the pipe itself. Flanged connections use strong bolts and rubber seals. Flanges allow for easier disassembly later if needed. Both methods are proven for dredging work.

(HDPE PE100 High Density Polyethylene Floating Water Mud Slurry Sand Gas Oil Dredging Dredge Dredger Mining Supply Plastic Pipe)

REQUEST A QUOTE

RELATED PRODUCTS

High Quality Industrial Plastic PVC Tube UPVC Pipe For Water With High Pressure

High Pressure HDPE Pipe for Water Supply Irrigation Agriculture Flexible Underground Drainage Roll-Industrial Construction

Industrial Hdpe Pipe Hdpe Water Main 2.5 Inch High Density Polyethylene Pipe 200mm Hdpe Pipe

Hdpe Water Pipe 3 6 10 12 Inch 32mm 200mm 1000mm Diameter 16 Bar Polyethylene s List Per Meter s

High Density Polyethylene Pipes Hdpe 4 Inch 5 Inch 6 Inch PE100 Hdpe Pipes Hdpe Water Pipe

High-Density Polyethylene (PE) Black Pipe for Gas Line Use

- Email: sales@pipesandfittings.net

- WeChat: +86 18337900677