LUOYANG DATANG ENERGY TECH CO.,LTD

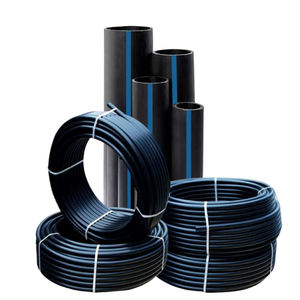

High-Density HDPE Pipe Durable High-Pressure Water Supply Polyethylene Tube s

PRODUCT PARAMETERS

Description

Introduction of High-Density HDPE Pipe Durable High-Pressure Water Supply Polyethylene Tube s

High Density Polyethylene Pipe (PE Pipe) is a durable and flexible thermoplastic piping solution widely used in industrial, municipal, agricultural, and mining applications. Known for its excellent chemical resistance, high impact strength, and long service life, PE pipes are ideal for transporting water, gases, and other fluids under varying pressure conditions.

Key Features of High-Density HDPE Pipe Durable High-Pressure Water Supply Polyethylene Tube s

Corrosion & Chemical Resistance

Resistant to rust, scale, and most chemicals, making it suitable for aggressive environments.

Lightweight & Flexible

Easy to transport and install due to low weight; flexibility allows bending without joints in certain applications.

High Impact Strength

Withstands extreme weather conditions and physical stress, reducing breakage risks.

Leak-Free Joints

Heat-fused joints create seamless connections, minimizing leakage risks.

Long Service Life

UV-resistant and abrasion-proof, with a lifespan exceeding 50 years under proper conditions.

Smooth Inner Surface

Reduces friction loss, improving flow efficiency and lowering energy costs.

Eco-Friendly

Non-toxic, recyclable, and compliant with drinking water safety standards.

Cost-Effective

Lower installation and maintenance costs compared to traditional materials (e.g., metal, concrete).

(High-Density HDPE Pipe Durable High-Pressure Water Supply Polyethylene Tube s )

Specifications of High-Density HDPE Pipe Durable High-Pressure Water Supply Polyethylene Tube s

High-density polyethylene pipes manage tough jobs. These HDPE pipelines provide water under high stress. The product is very solid and stands up to many points. HDPE doesn’t rot or corrode like metal pipelines. Chemicals in soil or water usually don’t damage it. It combats corrosion and scale buildup inside the pipeline wall surface. This maintains water flowing openly for a very long time.

The pipe surface is smooth. This level of smoothness indicates much less friction for the water. You get excellent circulation prices without needing huge pumps. Less energy is utilized pressing water via. That conserves money in time. The pipe material is also very adaptable. It flexes slightly without breaking. This assists throughout installation over uneven ground. It can take care of ground movement better than rigid pipelines.

These pipelines function well under high stress. They manage demanding water systems. Usual stress rankings are PN10, PN12.5, PN16, also greater. The rating informs you the optimum functioning pressure. Pick the right PN score for your project’s needs. Available sizes cover numerous applications. Sizes begin tiny, like 20mm or 25mm. They rise to plus sizes like 630mm or bigger. Wall thickness boosts for larger diameters and higher pressure ratings.

Installation methods are effective. Butt welding fuses pipe ends with each other perfectly. This makes a joint as solid as the pipe itself. Electrofusion utilizes special fittings with integrated heating systems. Flanged links work where you need to detach parts later. The pipes are light compared to steel or concrete. This makes handling and installing them a lot easier. Workers move areas rapidly. Less heavy equipment might be needed on site.

HDPE pipelines last years. They carry out accurately in water system networks. They are good for industrial procedure lines bring water. Agricultural watering systems use them commonly. They match trenchless setups like directional exploration. The pipelines hold up against harsh underground conditions. Sunshine can harm HDPE if left revealed for several years. Always hide the pipe or usage protective coverings above ground.

(High-Density HDPE Pipe Durable High-Pressure Water Supply Polyethylene Tube s )

Applications of High-Density HDPE Pipe Durable High-Pressure Water Supply Polyethylene Tube s

High-density polyethylene pipes handle difficult water jobs well. These HDPE tubes are unbelievably strong. They stand up to splitting and breaking under high pressure. Water streams efficiently inside since the wall surfaces are extremely smooth. This smoothness also suggests much less power pumps water with them. They don’t rust like metal pipelines. Chemicals in soil or water won’t harm them either. This makes them last years without requiring replacement.

Cities and communities utilize them for primary water lines underground. They bring drinking water securely to homes and organizations. Factories count on them for procedure water shipment. Mines utilize them to relocate slurry and water over fars away. Farms mount them for big watering systems across fields. Their flexibility aids them handle ground movement. They will not easily split if the earth shifts or ices up.

Signing up with these pipelines is simple and trusted. Warm combination melts completions together. This produces a smooth, leak-proof bond as solid as the pipe itself. No joints suggest fewer vulnerable points. Fewer weak spots imply fewer leakages. Much less water obtains shed. Repair prices remain reduced.

Fire divisions utilize them for high-pressure water supply lines. They carry out well under emergency situation problems. Building and construction sites require them for dewatering and short-lived supply. Their toughness resists damage from hefty tools. Marine jobs use them for consumptions and outfalls in seawater. The product withstands deep sea rust perfectly. Fairway mount them for sprinkler systems requiring consistent stress. Land programmers pick them for underground utility networks. They are affordable over the pipeline’s lengthy life.

Packing and Shipment

Depends on the products and qty,we could make the packing of coiling,rolls,bundle packing,crates or boxes,etc.

Shipment:By sea,railway,by air or as customer’s request.

Company Profile

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding HDPE Pipe Fitting, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net

Payment Terms

T/T,L/C at sight,Western Union & Paypal,etc.

5 FAQs of High-Density HDPE Pipe Durable High-Pressure Water Supply Polyethylene Tube s

What makes HDPE pipe good for high pressure?

HDPE pipe is very strong. Its high-density material resists internal pressure well. This pipe handles constant high water pressure reliably. It doesn’t burst easily under stress. Designers rate it for specific pressure classes. Always check the pipe’s pressure rating matches your project needs. Temperature affects the pressure it can safely hold too.

How long does HDPE pipe last underground?

HDPE pipe lasts a very long time underground. It resists corrosion and chemical attack. Rust doesn’t affect it like metal pipes. HDPE won’t rot or degrade like some materials. Underground installation protects it from sunlight damage. Expect decades of service life. Proper installation helps achieve maximum lifespan.

Is HDPE pipe hard to install?

HDPE pipe is easier to handle than many rigid pipes. Its flexibility is a big advantage. You can bend it around obstacles easily. This reduces the need for extra fittings. It’s lighter than metal or concrete pipe. Workers move and position it faster. Specialized fusion tools join sections securely. Trenching requirements are often simpler.

Why use HDPE instead of metal pipe?

HDPE beats metal pipe in key ways. Corrosion is the biggest problem with metal. HDPE won’t rust or corrode inside or out. Chemical resistance is superior. It doesn’t need linings or coatings. HDPE is much lighter for handling. It also stays smoother inside over time. Flow stays efficient. Leaks are less likely with fused joints.

How do you connect HDPE pipe sections?

Fusion joining is the standard method. Heat melts the ends of two pipe sections. You push the molten ends together. They cool into one solid, continuous piece. This creates a joint as strong as the pipe itself. Butt fusion works for straight sections. Electrofusion fittings join pipes to fittings or at angles. Mechanical connections exist but fusion is preferred for permanent lines.

(High-Density HDPE Pipe Durable High-Pressure Water Supply Polyethylene Tube s )

REQUEST A QUOTE

RELATED PRODUCTS

PN8~16 High Density Polyethylene HDPE Pipe Dn20mm Dn315mm`dn1000mm HDPE PIPE For Water Supply

Recycle HDPE Pipe Extrusion Grade High Density Polyethylene Plastic Raw Material

High Pressure HDPE Pipe for Water Supply Irrigation Agriculture Flexible Underground Drainage Roll-Industrial Construction

High Density Polyethylene HDPE Pipe 4 Inch 5 Inch 6 Inch PE100 Water Pipe Corrosion Resistant High Pressure Non-Toxic Anti-UV

High Pressure HDPE Pipe for Water Supply Irrigation Agriculture Flexible Underground Drainage Roll-Industrial Construction

PE Tube High Density Polyethylene Pipe HDPE Pipe For Water Supply Hdpe Siphon Co-Layered Drainage Pipes

- Email: sales@pipesandfittings.net

- WeChat: +86 18337900677