LUOYANG DATANG ENERGY TECH CO.,LTD

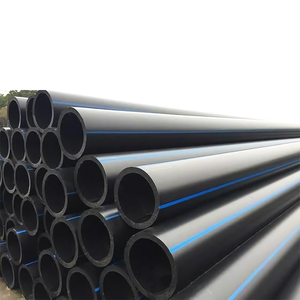

High-Density Polyethylene (HDPE) Water Supply Pipe – Non-Toxic and Durable

PRODUCT PARAMETERS

Description

Introduction of High-Density Polyethylene (HDPE) Water Supply Pipe – Non-Toxic and Durable

High Density Polyethylene Pipe (PE Pipe) is a durable and flexible thermoplastic piping solution widely used in industrial, municipal, agricultural, and mining applications. Known for its excellent chemical resistance, high impact strength, and long service life, PE pipes are ideal for transporting water, gases, and other fluids under varying pressure conditions.

Key Features of High-Density Polyethylene (HDPE) Water Supply Pipe – Non-Toxic and Durable

Corrosion & Chemical Resistance

Resistant to rust, scale, and most chemicals, making it suitable for aggressive environments.

Lightweight & Flexible

Easy to transport and install due to low weight; flexibility allows bending without joints in certain applications.

High Impact Strength

Withstands extreme weather conditions and physical stress, reducing breakage risks.

Leak-Free Joints

Heat-fused joints create seamless connections, minimizing leakage risks.

Long Service Life

UV-resistant and abrasion-proof, with a lifespan exceeding 50 years under proper conditions.

Smooth Inner Surface

Reduces friction loss, improving flow efficiency and lowering energy costs.

Eco-Friendly

Non-toxic, recyclable, and compliant with drinking water safety standards.

Cost-Effective

Lower installation and maintenance costs compared to traditional materials (e.g., metal, concrete).

(High-Density Polyethylene (HDPE) Water Supply Pipe – Non-Toxic and Durable)

Specifications of High-Density Polyethylene (HDPE) Water Supply Pipe – Non-Toxic and Durable

High-Density Polyethylene (HDPE) supply of water pipes deliver risk-free, reliable water. These pipelines are safe. They fulfill rigorous NSF/ANSI 61 requirements for drinking water safety and security. You obtain tidy water without hazardous chemicals leaching in.

HDPE pipelines are extremely challenging. They stand up to deterioration completely. Steel pipes rust. These don’t. They manage lots of chemicals located in soil or water treatment. Influence resistance is high. They will not fracture easily under stress and anxiety. This material lasts decades below ground. It makes it through severe weather and temperature swings.

Stress handling is excellent. HDPE pipelines work for various pressure courses. Usual ratings include PN6, PN8, PN10, PN12.5, PN16. This covers various water supply requires. The pipelines deal with chilly water well. They carry out fine in temperature levels up to 45 ° C(113 ° F). Avoid really high warmth sources.

Installment is simple. HDPE pipes are flexible. This aids them adhere to the ground’s shape. Trenching is less complex. You need fewer fittings. The pipelines are light. Moving and handling them is easy. Joints use heat fusion. This creates an irreversible, watertight seal. The pipe and suitable melt with each other. This bond is as strong as the pipeline itself. Drip points vanish.

Sizes are extensively offered. Sizes range from tiny 20mm (3/4″) align to large 1200mm (48″) keys. Common sizes keep links efficient. Wall thickness complies with conventional measurement proportions like SDR11, SDR17, SDR26. Thicker walls handle higher pressures. The smooth internal surface area minimizes rubbing. Water moves efficiently. Pumping prices stay lower. Clogging from scale buildup is uncommon. Upkeep demands are minimal.

(High-Density Polyethylene (HDPE) Water Supply Pipe – Non-Toxic and Durable)

Applications of High-Density Polyethylene (HDPE) Water Supply Pipe – Non-Toxic and Durable

High-density polyethylene pipes supply safe drinking water. This plastic material is safe. It meets stringent food-grade safety requirements. You won’t find unsafe chemicals seeping right into your water. HDPE pipes maintain water tidy and risk-free for families. They are extremely challenging. These pipelines resist deterioration perfectly. Rust and range build-up inside the pipeline isn’t an issue. This maintains water moving efficiently for many years. HDPE handles high pressure well. It will not break easily under anxiety. Anticipate these pipes to last decades without trouble.

Leaks are a significant frustration with old pipelines. HDPE solves this. The pipeline material itself is really strong. Joints are merged together utilizing heat. This produces a seamless, permanent bond more powerful than the pipe itself. Leak points typical at threaded links go away. You save water and avoid costly repairs. Installation is less complex as well. HDPE pipes are much lighter than metal or concrete pipes. Employees handle them easily. This reduces labor costs and speeds up projects. Trenching needs are usually much less demanding. The flexibility of HDPE assists. It flexes somewhat to follow the ground contours. This minimizes the demand for extra fittings. Less installations indicate less potential leak spots.

These benefits make HDPE suitable for many water tasks. Districts use it for new main water lines. It’s ideal for replacing old, falling short steel pipelines underground. Builders choose HDPE for water solution lines to homes and structures. Manufacturing facilities rely on it for process water distribution. Farms make use of HDPE pipes for irrigation systems throughout fields. Its sturdiness deals with exposure to sunshine and weather condition. Miners use it for dewatering operations. HDPE works dependably for aquatic outfalls. It holds up against extreme saltwater conditions.

Packing and Shipment

Depends on the products and qty,we could make the packing of coiling,rolls,bundle packing,crates or boxes,etc.

Shipment:By sea,railway,by air or as customer’s request.

Company Profile

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding HDPE Pipe Fitting, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net

Payment Terms

T/T,L/C at sight,Western Union & Paypal,etc.

5 FAQs of High-Density Polyethylene (HDPE) Water Supply Pipe – Non-Toxic and Durable

What is HDPE pipe? HDPE pipe is made from high-density polyethylene plastic. This material is strong and flexible. People use it for water supply systems. It moves drinking water efficiently.

Why is HDPE pipe non-toxic? HDPE uses food-safe materials. It meets strict health standards. The pipe won’t release chemicals into water. Your water stays pure and safe.

How durable is HDPE pipe? HDPE resists rust and chemicals. It handles extreme weather. It doesn’t crack in freezing conditions. The pipe lasts over 50 years.

Can HDPE pipe handle high pressure? Yes, HDPE is built for pressure. It has thick walls. It won’t burst easily. Water flows smoothly through it.

Is HDPE pipe easy to install? HDPE is lightweight. It bends around obstacles. Workers connect it quickly. Fewer joints mean less leakage risk. This saves time and money.

(High-Density Polyethylene (HDPE) Water Supply Pipe – Non-Toxic and Durable)

REQUEST A QUOTE

RELATED PRODUCTS

High Quality Plastic Pipe 5 6 8 10 Inch Diameter Pvc Water Pipe 300mm 600mm Water Upvc Pipe Size

HDPE Flexible Construction Plastic Tubes High Pressure Underground Water Supply Industrial Pressure System Drainage Tubing 6mm

PE100 Grade High Density Polyethylene (HDPE) Pipe for Natural Gas Water Irrigation Drainage Municipal Purposes-round Head

HDPE High-Density Polyethylene Corrugated Perforated Grooved Drainage Plastic Pipe New Type Lightweight Durable Material

High Quality Industrial Plastic PVC Tube UPVC Pipe For Water With High Pressure

High Pressure HDPE Pipe for Water Supply Irrigation Agriculture Flexible Underground Drainage Roll-Industrial Construction

- Email: sales@pipesandfittings.net

- WeChat: +86 18337900677