LUOYANG DATANG ENERGY TECH CO.,LTD

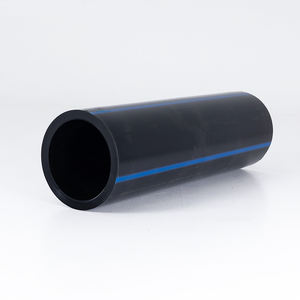

High Density Polyethylene Tube HDPE Pipe

PRODUCT PARAMETERS

Description

Introduction of High Density Polyethylene Tube HDPE Pipe

High Density Polyethylene Pipe (PE Pipe) is a durable and flexible thermoplastic piping solution widely used in industrial, municipal, agricultural, and mining applications. Known for its excellent chemical resistance, high impact strength, and long service life, PE pipes are ideal for transporting water, gases, and other fluids under varying pressure conditions.

Key Features of High Density Polyethylene Tube HDPE Pipe

Corrosion & Chemical Resistance

Resistant to rust, scale, and most chemicals, making it suitable for aggressive environments.

Lightweight & Flexible

Easy to transport and install due to low weight; flexibility allows bending without joints in certain applications.

High Impact Strength

Withstands extreme weather conditions and physical stress, reducing breakage risks.

Leak-Free Joints

Heat-fused joints create seamless connections, minimizing leakage risks.

Long Service Life

UV-resistant and abrasion-proof, with a lifespan exceeding 50 years under proper conditions.

Smooth Inner Surface

Reduces friction loss, improving flow efficiency and lowering energy costs.

Eco-Friendly

Non-toxic, recyclable, and compliant with drinking water safety standards.

Cost-Effective

Lower installation and maintenance costs compared to traditional materials (e.g., metal, concrete).

(High Density Polyethylene Tube HDPE Pipe)

Specifications of High Density Polyethylene Tube HDPE Pipe

High density polyethylene tube uses strong advantages. This material withstands deterioration exceptionally well. It handles lots of chemicals without damage. HDPE pipe does not corrosion. It lasts a long time underground. You discover it ideal for water, gas, and slurry systems.

These pipelines are available in many dimensions. Sizes typically range from tiny 16mm align to huge 1600mm keys. Wall surface thickness depends upon the pipeline’s SDR rating. SDR suggests Basic Measurement Proportion. A reduced SDR number means a thicker wall surface. Thicker wall surfaces take care of higher pressures.

Stress scores are important. They are called PN ratings. PN stands for Stress Small. Typical PN rankings consist of PN6, PN8, PN10, PN12.5, and PN16. The PN number indicates the maximum pressure the pipeline can manage in bars. PN10 pipeline safely manages 10 bar pressure. This equals concerning 145 psi. The Hydrostatic Layout Basis identifies the lasting toughness. HDPE pipeline usually has an HDB of 8.0 MPa or 10.0 MPa. This guarantees years of trusted solution.

Temperature level range issues for performance. Criterion HDPE pipeline functions efficiently from -40 ° C as much as 60 ° C. It remains versatile in freezing problems. It keeps its shape in cozy atmospheres. Prevent utilizing it above 60 ° C lasting. Heat lowers its pressure capacity.

Jointing techniques are easy and reputable. Butt combination welding thaws the pipeline ends together. This creates a seamless, watertight link strong as the pipe itself. Electrofusion utilizes special installations with integrated heating elements. Flange adapters connect HDPE to other pipeline products like steel or valves. These techniques ensure safe and secure systems. HDPE pipe withstands ground movement well. Its versatility assists it take in stress and anxiety. It resists breaking under pressure rises.

(High Density Polyethylene Tube HDPE Pipe)

Applications of High Density Polyethylene Tube HDPE Pipe

High Thickness Polyethylene (HDPE) pipe is difficult stuff. It deals with pressure well. It doesn’t corrosion or rot. Chemicals don’t injure it a lot. This makes it perfect for great deals of jobs.

Cities use HDPE pipeline for water. It carries drinking water safely. It will not add negative preferences. It benefits relocating wastewater as well. Leakages are rare because joints fuse with each other. This saves water and cash.

Gas companies rely on HDPE pipe. It securely transfers gas underground. The material is really strong. It resists splits well. This stops harmful leakages. It’s a trusted option for fuel lines.

Mines require challenging pipes. HDPE pipeline delivers. It lugs slurry and tailings. Unpleasant materials do not wear it out fast. It deals with the harsh mining environment. Its light weight aids setup too.

Factories use HDPE pipeline within. It moves chemicals safely. Acids and bases create little damages. It helps water cooling systems. Its smooth inside keeps circulation high. This saves pumping energy.

Farmers use HDPE pipeline for watering. It in 2015 in sunlight and dirt. It won’t damage down from fertilizers. It’s adaptable for laying around fields. Drip lines usually make use of smaller sized HDPE tubes. It brings water right to the plants.

Telecom firms placed cables inside HDPE conduit. It shields wires underground. It shields versus dampness and crushing. Installment is quick with trenchless techniques. This maintains expenses lower.

Land fills use HDPE linings and pipelines. It collects leachate liquid securely. Its chemical resistance is vital below. It stops contamination from spreading. It’s crucial for environmental security.

HDPE pipe installs quick. It flexes to comply with the ground. Warmth fusion makes joints more powerful than the pipe itself. This suggests no vulnerable points. It survives ground activity far better than rigid pipes. Its lengthy life means less excavating later.

Packing and Shipment

Depends on the products and qty,we could make the packing of coiling,rolls,bundle packing,crates or boxes,etc.

Shipment:By sea,railway,by air or as customer’s request.

Company Profile

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding HDPE Pipe Fitting, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net

Payment Terms

T/T,L/C at sight,Western Union & Paypal,etc.

5 FAQs of High Density Polyethylene Tube HDPE Pipe

What is HDPE pipe? HDPE pipe means High-Density Polyethylene pipe. It’s a strong plastic tube. Factories make it from petroleum. The material is very tough. It resists cracks well. Builders use it for moving water, gas, or chemicals underground.

Why choose HDPE over metal pipes? HDPE beats metal in many ways. It won’t rust or corrode. Metal pipes rust over time. HDPE lasts much longer underground. It bends easily without breaking. You don’t need as many fittings. Installation is faster. HDPE handles ground movement better. Metal pipes can crack.

How much pressure can HDPE pipe handle? HDPE handles high pressure fine. Standard pipes manage 80 PSI to 160 PSI. Industrial grade pipes handle much higher pressures. The exact rating depends on the pipe size and wall thickness. Manufacturers label the pressure rating clearly. Always check this rating before installing it.

What temperatures work for HDPE pipe? HDPE works in hot and cold weather. It stays flexible down to -40°F. It handles heat up to 140°F for water. Short spikes to 180°F are okay. Avoid constant high heat. Extreme cold makes HDPE stiffer. But it usually doesn’t become brittle.

Can HDPE pipe carry chemicals? Yes, HDPE carries many chemicals safely. It resists most acids, bases, and salts. It handles fuels and alcohols well. Always check chemical compatibility charts first. Some strong solvents can damage HDPE. Know what you’re putting inside the pipe.

(High Density Polyethylene Tube HDPE Pipe)

REQUEST A QUOTE

RELATED PRODUCTS

PN8~16 High Density Polyethylene HDPE Pipe Dn20mm Dn315mm`dn1000mm HDPE PIPE For Water Supply

High-quality PE Pipes PN12, PN16, SDR11, SDR21, PE100, 110 Mm, 150 Mm, 250 Mm, 900 Mm, DN1000 Large Diameter PE Pipes

Durable HDPE Corrugated Flexible Irrigation & Drainage Pipe High-Density Polyethylene Underground Cable Protection Plastic Tubes

PE Tube High Density Polyethylene Pipe HDPE Pipe For Water Supply Hdpe Siphon Co-Layered Drainage Pipes

PN8~16 High Density Polyethylene HDPE Pipe Dn20mm Dn315mm`dn1000mm HDPE PIPE For Water Supply

High-Density Polyethylene (PE) Black Pipe for Gas Line Use

- Email: sales@pipesandfittings.net

- WeChat: +86 18337900677