LUOYANG DATANG ENERGY TECH CO.,LTD

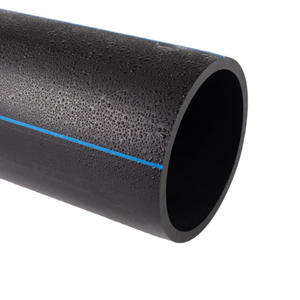

High Density Polyethylene Tube HDPE Pipes PE Water Pipe For Supply And Drainage

PRODUCT PARAMETERS

Description

Introduction of High Density Polyethylene Tube HDPE Pipes PE Water Pipe For Supply And Drainage

High Density Polyethylene Pipe (PE Pipe) is a durable and flexible thermoplastic piping solution widely used in industrial, municipal, agricultural, and mining applications. Known for its excellent chemical resistance, high impact strength, and long service life, PE pipes are ideal for transporting water, gases, and other fluids under varying pressure conditions.

Key Features of High Density Polyethylene Tube HDPE Pipes PE Water Pipe For Supply And Drainage

Corrosion & Chemical Resistance

Resistant to rust, scale, and most chemicals, making it suitable for aggressive environments.

Lightweight & Flexible

Easy to transport and install due to low weight; flexibility allows bending without joints in certain applications.

High Impact Strength

Withstands extreme weather conditions and physical stress, reducing breakage risks.

Leak-Free Joints

Heat-fused joints create seamless connections, minimizing leakage risks.

Long Service Life

UV-resistant and abrasion-proof, with a lifespan exceeding 50 years under proper conditions.

Smooth Inner Surface

Reduces friction loss, improving flow efficiency and lowering energy costs.

Eco-Friendly

Non-toxic, recyclable, and compliant with drinking water safety standards.

Cost-Effective

Lower installation and maintenance costs compared to traditional materials (e.g., metal, concrete).

(High Density Polyethylene Tube HDPE Pipes PE Water Pipe For Supply And Drainage)

Specifications of High Density Polyethylene Tube HDPE Pipes PE Water Pipe For Supply And Drainage

High thickness polyethylene tubes, called HDPE or PE pipes, are solid pipes utilized for water supply and drainage. They are made from resilient plastic. This plastic lasts long and stands up to damages well. HDPE pipes take care of high stress. They benefit water scooting inside them. The pipe walls are thick yet flexible. This adaptability helps during installment. Employees can bend the pipelines somewhat around challenges. This saves time and labor costs.

These pipelines withstand pressure. Their smooth inside stops build-up. Water streams easily. Scale and deposits don’t stick quickly. HDPE does not rust like metal pipes. It overlooks deterioration from dirt chemicals or water. This makes it best for underground usage. You do not need added layers. The product also fights many chemicals. It matches various water types and drain tasks.

Joining HDPE pipelines is reliable. Employees warm fuse the ends with each other. This creates a strong, watertight joint. The joint is as solid as the pipeline itself. There are no weak points. This combination approach stops leaks long-term. The pipeline material is extremely tough. It resists fractures and impacts. It takes care of ground activity much better than rigid pipelines. HDPE pipes are lightweight. Delivering them is simple. Installing them is quicker than heavier materials.

The pipelines are available in basic sizes. Typical sizes range from tiny to very large. Wall density adheres to SDR rankings. SDR reveals the stress rating. A lower SDR number indicates a thicker wall. Thicker walls take care of greater pressure. These pipelines carry drinking water securely. They fulfill rigorous wellness standards. They additionally work for wastewater, sewage, and commercial water drainage. Their sturdiness manages rough problems underground. They execute reliably for decades.

(High Density Polyethylene Tube HDPE Pipes PE Water Pipe For Supply And Drainage)

Applications of High Density Polyethylene Tube HDPE Pipes PE Water Pipe For Supply And Drainage

HDPE pipes are plastic tubes made from strong polyethylene material. People use these pipelines a whole lot for moving water. They function well for bringing clean water to homes and businesses. HDPE pipes carry alcohol consumption water securely. They are likewise good for ranches. Farmers use them for watering systems to water plants. These pipes are difficult and last a very long time.

HDPE pipes are also exceptional for drainage tasks. They deal with wastewater from residences and buildings. Towns use large HDPE pipelines for sewer systems. These pipelines handle sewer flow successfully. They are likewise used for stormwater water drainage. HDPE pipes help manage rain overflow, preventing floods. Building sites rely on them for dewatering, eliminating unwanted groundwater.

These pipelines are prominent for many reasons. They withstand corrosion and rust completely. Chemicals in soil or water do not harm them. HDPE pipes are really adaptable. This adaptability helps them take care of ground motion well. They are lightweight, making them much easier to carry and mount than metal pipelines. Employees can join them rapidly utilizing warm fusion. This develops extremely strong, leak-proof connections.

The smooth inside surface area of HDPE pipelines is very important. Water moves conveniently with them with less friction. This suggests reduced pumping expenses gradually. HDPE pipes are sturdy under stress. They carry out dependably in various ground conditions. Industries use them for various liquids past water. Mines, factories, and gas energies install HDPE pipe networks. Garbage dumps utilize them for collecting leachate safely. HDPE pipelines supply a reliable service for numerous water system and drainage demands.

Packing and Shipment

Depends on the products and qty,we could make the packing of coiling,rolls,bundle packing,crates or boxes,etc.

Shipment:By sea,railway,by air or as customer’s request.

Company Profile

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding HDPE Pipe Fitting, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net

Payment Terms

T/T,L/C at sight,Western Union & Paypal,etc.

5 FAQs of High Density Polyethylene Tube HDPE Pipes PE Water Pipe For Supply And Drainage

Here are 5 FAQs about High Density Polyethylene (HDPE) Tubes/Pipes for Water Supply and Drainage:

1. What is HDPE pipe?

HDPE pipe is plastic tubing. It’s made from High-Density Polyethylene. This material is very tough. It resists chemicals and impact well. HDPE pipes are flexible. They handle pressure effectively. They are common for moving water underground.

2. Why use HDPE instead of metal or concrete pipes?

HDPE offers big advantages. It doesn’t rust or corrode. Chemicals in soil or water won’t damage it. It’s much lighter than metal or concrete. This makes transport easier. Installation is faster too. HDPE pipes are very smooth inside. This reduces friction. Water flows better. Less energy pumps water. Leaks are rare. The pipes fuse together seamlessly.

3. Where can we use these HDPE pipes?

Use HDPE pipes for many water jobs. They are perfect for main drinking water lines. They work for moving raw water. They handle sewage and drainage systems well. Industrial plants use them for process water. HDPE suits mining slurry transport. It’s good for irrigation systems. Use it for gas lines too.

4. How do you connect HDPE pipe sections?

The main method is heat fusion. This melts the pipe ends together. It creates a joint as strong as the pipe itself. Butt fusion joins pipe ends directly. Electrofusion uses special fittings with heating elements. Flanged connections work for linking to valves or pumps. Proper fusion needs trained crews and the right tools.

5. How long do HDPE pipes last?

HDPE pipes last a very long time. Expect 50 years or more. They resist environmental stress cracking well. They handle ground movement better than rigid pipes. Sunlight (UV) can degrade them above ground. Bury them or use special UV-protected versions outdoors. Correct installation is key for maximum life.

(High Density Polyethylene Tube HDPE Pipes PE Water Pipe For Supply And Drainage)

REQUEST A QUOTE

RELATED PRODUCTS

High Quality HDPE Water Pipe and Fitting

PE100 HDPE PIPE SDR 9 11 13.6 17 21 26 33 41 1.6Mpa Black HDPE Pipe High Density Polyethylene PE Water Pipe for Water Supply

High-Density HDPE Pipe Durable High-Pressure Water Supply Polyethylene Tube s

PE100 Grade High Density Polyethylene (HDPE) Pipe for Natural Gas Water Irrigation Drainage Municipal Purposes-round Head

High Pressure HDPE Pipe Water Supply Irrigation Agriculture Electro Fusion Fitting Underground Drainage Industrial Construction

High-quality PE Pipes PN12, PN16, SDR11, SDR21, PE100, 110 Mm, 150 Mm, 250 Mm, 900 Mm, DN1000 Large Diameter PE Pipes

- Email: sales@pipesandfittings.net

- WeChat: +86 18337900677