LUOYANG DATANG ENERGY TECH CO.,LTD

High Pressure HDPE Pipe Water Supply Irrigation Agriculture Electro Fusion Fitting Underground Drainage Industrial Construction

PRODUCT PARAMETERS

Description

Introduction of High Pressure HDPE Pipe Water Supply Irrigation Agriculture Electro Fusion Fitting Underground Drainage Industrial Construction

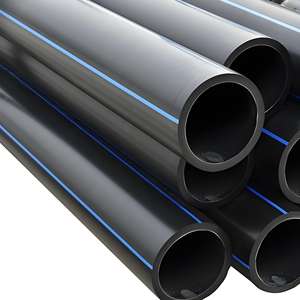

High Density Polyethylene Pipe (PE Pipe) is a durable and flexible thermoplastic piping solution widely used in industrial, municipal, agricultural, and mining applications. Known for its excellent chemical resistance, high impact strength, and long service life, PE pipes are ideal for transporting water, gases, and other fluids under varying pressure conditions.

Key Features of High Pressure HDPE Pipe Water Supply Irrigation Agriculture Electro Fusion Fitting Underground Drainage Industrial Construction

Corrosion & Chemical Resistance

Resistant to rust, scale, and most chemicals, making it suitable for aggressive environments.

Lightweight & Flexible

Easy to transport and install due to low weight; flexibility allows bending without joints in certain applications.

High Impact Strength

Withstands extreme weather conditions and physical stress, reducing breakage risks.

Leak-Free Joints

Heat-fused joints create seamless connections, minimizing leakage risks.

Long Service Life

UV-resistant and abrasion-proof, with a lifespan exceeding 50 years under proper conditions.

Smooth Inner Surface

Reduces friction loss, improving flow efficiency and lowering energy costs.

Eco-Friendly

Non-toxic, recyclable, and compliant with drinking water safety standards.

Cost-Effective

Lower installation and maintenance costs compared to traditional materials (e.g., metal, concrete).

(High Pressure HDPE Pipe Water Supply Irrigation Agriculture Electro Fusion Fitting Underground Drainage Industrial Construction)

Specifications of High Pressure HDPE Pipe Water Supply Irrigation Agriculture Electro Fusion Fitting Underground Drainage Industrial Construction

High stress HDPE pipe fixes hard water work. It lugs water for farms, cities, and factories. You need strong fittings as well. Electro Fusion installations join HDPE pipeline completely underground. They take care of large pressure, up to PN16 or PN20 rankings. These installations help drinking supply of water. They help plant watering systems. They help factory water drainage underground.

The pipeline is difficult polyethylene plastic. It will not rust or rot. Chemicals in dirt or water don’t damage it. It bends a little. This helps around obstacles. The smooth inside maintains water streaming quick. Much less power pumps the water. Saves money long-term.

Electro Blend installations make solid, leak-proof connections. You clean the pipe ends. You put the suitable on. An electric maker thaws the plastic with each other. It bonds the pipe and suitable right into one item. This joint is as strong as the pipe itself. It manages stress rises. It lasts years below ground. No leakages assured.

Many fitting kinds exist. Use tees to divide water lines. Use elbow joints to alter instructions. Use combinings to attach straight pipes. Usage reducers for various pipe dimensions. Caps shut down lines. All sizes are readily available. Usual sizes are 20mm as much as 800mm or bigger. Select the size for your flow requires.

This system installs quick. Combination welding defeats old adhesive or flanges. It needs much less digging time. Less labor price. The light-weight pipeline actions easily. Workers manage it securely. Once buried, it needs almost no upkeep. It makes it through cold ground. It survives wet problems. It makes it through hefty tons above. Perfect for roadways or areas.

The material is risk-free for alcohol consumption water. It satisfies wellness standards. It doesn’t include bad tastes. No contaminants seep out. You trust this pipeline for homes and farms. Its long life makes tasks rewarding. Deals with tough conditions time after time. Solid plastic withstands.

(High Pressure HDPE Pipe Water Supply Irrigation Agriculture Electro Fusion Fitting Underground Drainage Industrial Construction)

Applications of High Pressure HDPE Pipe Water Supply Irrigation Agriculture Electro Fusion Fitting Underground Drainage Industrial Construction

High pressure HDPE pipe is a strong plastic pipeline. It resolves numerous problems for relocating liquids. Water networks use it widely. The pipe takes care of high stress easily. It brings clean drinking water to communities and cities. This pipe lasts a very long time. It doesn’t rust or rust like steel. Chemicals in soil or water don’t damage it. This conserves cash on fixings and replacements.

Farmers depend on HDPE pipeline for irrigation. It delivers water efficiently throughout fields. The smooth inside surface area indicates much less rubbing. Water streams faster making use of less pump power. This saves energy. Hidden HDPE pipeline stands up to damage from farming equipment. Animals or weather condition won’t injure it. Agriculture requires risk-free water transport. HDPE ensures no contamination of water or dirt.

Linking HDPE pipeline is simple with electro fusion fittings. These installations produce permanent, leak-free joints. Heat melts the pipe and fitting surface areas with each other. They fuse right into one solid item. This method is reliable for underground installments. Workers discover it fast to learn and make use of. Strong joints are crucial for stress systems. Electro fusion supplies this toughness.

Underground drainage systems benefit from HDPE. Its versatility enables it to flex slightly. This assists it work out safely in trenches. Ground activity seldom damages it. HDPE stands up to the weight of dirt and website traffic over. Drain water moves freely without blockages. The pipeline will not break down under tons.

Commercial building sites choose HDPE for tough jobs. Manufacturing facilities use it for procedure water and waste lines. Mining operations move slurry and chemicals via it. The material handles abrasion well. HDPE pipeline works in rough atmospheres. Chemical plants need corrosion-resistant piping. HDPE is commonly the most effective solution.

Packing and Shipment

Depends on the products and qty,we could make the packing of coiling,rolls,bundle packing,crates or boxes,etc.

Shipment:By sea,railway,by air or as customer’s request.

Company Profile

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding HDPE Pipe Fitting, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net

Payment Terms

T/T,L/C at sight,Western Union & Paypal,etc.

5 FAQs of High Pressure HDPE Pipe Water Supply Irrigation Agriculture Electro Fusion Fitting Underground Drainage Industrial Construction

People ask about HDPE pipes and electro fusion fittings often. Here are answers to five common questions.

Why pick HDPE pipe over metal for water? HDPE resists rust and chemicals much better than steel or iron. This means it lasts decades underground without leaking. It handles high pressure for irrigation or city water mains. The material is flexible too. It bends around obstacles easier during installation. This saves time and money on fittings.

How does electro fusion joining work? Electro fusion fittings have special coils inside. You clean the pipe ends perfectly. You put them into the fitting. You pass an electrical current through the coils. This melts the HDPE material inside the fitting and the pipe surface together. The melted material cools. It forms one solid, leak-proof piece. This joint is as strong as the pipe itself.

How long do HDPE pipes last? HDPE pipes are very tough. They withstand harsh soil conditions and chemicals. They don’t corrode. Properly installed HDPE systems easily last 50 years or more. This long life makes them cost-effective. You avoid frequent replacements common with older materials.

Is installing HDPE pipe difficult? Installing HDPE pipe is often easier than metal pipe. The pipes are lighter. Workers handle them easier. They connect using simple butt fusion or electro fusion methods. These methods need less heavy equipment than welding steel. Trained crews can install HDPE systems quickly. This reduces project time and labor costs.

Are HDPE pipes good value? Yes. The upfront cost might seem similar to some materials. Consider the total cost. HDPE lasts much longer. It needs almost no maintenance. Leaks are rare with good fusion joints. You save money on repairs and replacements over many years. Less downtime for repairs is another big benefit.

(High Pressure HDPE Pipe Water Supply Irrigation Agriculture Electro Fusion Fitting Underground Drainage Industrial Construction)

REQUEST A QUOTE

RELATED PRODUCTS

Hdpe Pipe s Hdpe Pipe Sdr11 Sdr17 Sdr 21 High Density Polyethylene Hdpe Pipe s

High Density Polyethylene HDPE Pipe 4 Inch 5 Inch 6 Inch PE100 Water Pipe Corrosion Resistant High Pressure Non-Toxic Anti-UV

High Quality PN16 PE Water & Irrigation Supply Pipe 20-110mm Black Polyethylene Plastic Tube

Factory Direct 1.6MPa HDPE Pipe Welding Butt Fusion Plastic Tubes Water Supply Drainage Polyethylene Pipe

High-Density PE Polyethylene Pipe Large Diameter 110mm-800mm Polyethylene Bellows Drainage

Recycle HDPE Pipe Extrusion Grade High Density Polyethylene Plastic Raw Material

- Email: sales@pipesandfittings.net

- WeChat: +86 18337900677