LUOYANG DATANG ENERGY TECH CO.,LTD

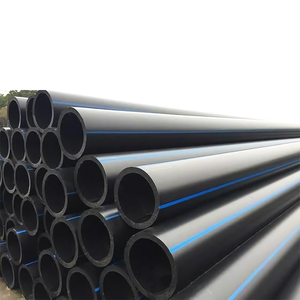

High-quality PE Pipes PN12, PN16, SDR11, SDR21, PE100, 110 Mm, 150 Mm, 250 Mm, 900 Mm, DN1000 Large Diameter PE Pipes

PRODUCT PARAMETERS

Description

Introduction of High-quality PE Pipes PN12, PN16, SDR11, SDR21, PE100, 110 Mm, 150 Mm, 250 Mm, 900 Mm, DN1000 Large Diameter PE Pipes

High Density Polyethylene Pipe (PE Pipe) is a durable and flexible thermoplastic piping solution widely used in industrial, municipal, agricultural, and mining applications. Known for its excellent chemical resistance, high impact strength, and long service life, PE pipes are ideal for transporting water, gases, and other fluids under varying pressure conditions.

Key Features of High-quality PE Pipes PN12, PN16, SDR11, SDR21, PE100, 110 Mm, 150 Mm, 250 Mm, 900 Mm, DN1000 Large Diameter PE Pipes

Corrosion & Chemical Resistance

Resistant to rust, scale, and most chemicals, making it suitable for aggressive environments.

Lightweight & Flexible

Easy to transport and install due to low weight; flexibility allows bending without joints in certain applications.

High Impact Strength

Withstands extreme weather conditions and physical stress, reducing breakage risks.

Leak-Free Joints

Heat-fused joints create seamless connections, minimizing leakage risks.

Long Service Life

UV-resistant and abrasion-proof, with a lifespan exceeding 50 years under proper conditions.

Smooth Inner Surface

Reduces friction loss, improving flow efficiency and lowering energy costs.

Eco-Friendly

Non-toxic, recyclable, and compliant with drinking water safety standards.

Cost-Effective

Lower installation and maintenance costs compared to traditional materials (e.g., metal, concrete).

(High-quality PE Pipes PN12, PN16, SDR11, SDR21, PE100, 110 Mm, 150 Mm, 250 Mm, 900 Mm, DN1000 Large Diameter PE Pipes)

Specifications of High-quality PE Pipes PN12, PN16, SDR11, SDR21, PE100, 110 Mm, 150 Mm, 250 Mm, 900 Mm, DN1000 Large Diameter PE Pipes

PE pipes made from PE100 material deal solid, trustworthy services for many fluid transportation needs. These pipelines deal with high stress applications well. PN12 and PN16 ratings show the stress capacity. PN16 pipes withstand greater pressure than PN12 pipelines.

The pipeline wall thickness matters greatly. SDR11 pipelines have thicker wall surfaces than SDR21 pipes. Thicker wall surfaces imply greater stress ratings for the exact same pipeline dimension. SDR11 pipes match high pressure systems. SDR21 pipelines function well for reduced pressure needs.

Readily available diameters satisfy varied project needs. Smaller sized dimensions like 110mm and 150mm prevail for local distribution lines. Bigger sizes, including 250mm, 900mm, and also DN1000 (1000mm), manage significant transmission mains. These large pipes relocate considerable volumes effectively.

PE100 is the preferred material grade. It provides superb toughness and long-term strength. This product stands up to splits and stands up to ground movements. It performs accurately over decades. Chemical resistance is one more essential benefit. PE100 pipes handle lots of aggressive materials without rust.

These pipes are lightweight contrasted to conventional products like steel or concrete. This makes transport and installation much easier and quicker. Jointing usages basic warm fusion methods. This produces smooth, leak-proof connections. The smooth internal surface decreases rubbing loss. Circulation ability stays high.

Applications cover water system, gas circulation, watering, and industrial usages. The combination of PE100 material, exact pressure rankings (PN12, PN16), regulated wall density (SDR11, SDR21), and full dimension array makes sure the best pipe for the work. Durability and low upkeep include significant value.

(High-quality PE Pipes PN12, PN16, SDR11, SDR21, PE100, 110 Mm, 150 Mm, 250 Mm, 900 Mm, DN1000 Large Diameter PE Pipes)

Applications of High-quality PE Pipes PN12, PN16, SDR11, SDR21, PE100, 110 Mm, 150 Mm, 250 Mm, 900 Mm, DN1000 Large Diameter PE Pipes

Premium PE pipes in PN12, PN16, SDR11, and SDR21 pressure courses supply reputable performance across many fields. These PE100 material pipes manage demanding tasks with toughness and flexibility. Sizes like 110mm, 150mm, and 250mm fit smaller-scale installations. Bigger sizes such as 900mm and DN1000 handle significant facilities tasks efficiently.

Water networks utilize these pipes extensively. Their corrosion resistance guarantees tidy water distribution. Leak-proof joints keep system integrity. Smooth inner walls lower rubbing, conserving pumping power. Municipalities install them for main lines and circulation grids. Country water tasks depend on their very easy transport and fast setting up.

Gas circulation systems benefit from PE pipes’ safety and security attributes. They withstand breaking and stand up to ground activity. Blend welding develops smooth connections, eliminating leak dangers. Operators choose PN16-rated pipes for medium-pressure gas lines. Upkeep needs decrease substantially compared to steel options.

Industrial applications manipulate their chemical resistance. Manufacturing facilities utilize them for hostile fluids or slurry transport. Mining procedures lay PE pipes for tailings and procedure water. SDR11 pipelines deal with greater stress in chemical plants. Their lightweight nature simplifies setup in limited areas.

Large-diameter PE pipes change metropolitan infrastructure. DN1000 pipes serve as main water transmission mains. They change maturing concrete or steel lines with very little disruption. Wastewater therapy plants utilize them for inlet and outlet networks. Marine outfalls release these pipelines for salt water intake and discharge. Trenchless techniques like directional boring install them under roadways or rivers quickly.

Agricultural watering relies on resilient PE solutions. Farmers lay 150mm and 250mm pipes for pivot systems and canals. UV-stabilized variations endure sun direct exposure in open fields. Frost resistance avoids wintertime damages in chilly regions.

Packing and Shipment

Depends on the products and qty,we could make the packing of coiling,rolls,bundle packing,crates or boxes,etc.

Shipment:By sea,railway,by air or as customer’s request.

Company Profile

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding HDPE Pipe Fitting, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net

Payment Terms

T/T,L/C at sight,Western Union & Paypal,etc.

5 FAQs of High-quality PE Pipes PN12, PN16, SDR11, SDR21, PE100, 110 Mm, 150 Mm, 250 Mm, 900 Mm, DN1000 Large Diameter PE Pipes

What pressure can PN12 and PN16 pipes handle?

PN12 pipes handle 12 bar pressure. PN16 pipes handle 16 bar pressure. Choose PN16 for higher pressure needs. Both ratings ensure safe operation under their specified loads.

What sizes do you offer?

We stock many common sizes. You find 110mm, 150mm, 250mm, 900mm pipes here. We also supply large DN1000 pipes. This range covers most project needs from small lines to major mains.

Why use PE100 material?

PE100 is top-grade polyethylene. It delivers excellent strength. It resists cracks well. It handles high pressure efficiently. It offers great chemical resistance. PE100 pipes last decades underground. They are very reliable.

How do SDR11 and SDR21 differ?

SDR11 pipes have thicker walls. They handle higher pressure. SDR21 pipes have thinner walls. They suit lower pressure applications. Both are PE100 material. The SDR number tells you the wall thickness relative to the pipe size.

Are these pipes easy to install?

Yes, PE pipes are very easy to install. They are much lighter than metal pipes. This makes handling simple. Fusion welding joins sections securely. This creates leak-proof systems. Proper equipment ensures strong joints. PE won’t rust or corrode. It saves long-term maintenance costs.

(High-quality PE Pipes PN12, PN16, SDR11, SDR21, PE100, 110 Mm, 150 Mm, 250 Mm, 900 Mm, DN1000 Large Diameter PE Pipes)

REQUEST A QUOTE

RELATED PRODUCTS

High-Density Polyethylene (HDPE) Composite Pipes HDPE Steel Wire Pipe for Water Supply

High-Density Polyethylene (HDPE) Composite Pipes HDPE Steel Wire Pipe for Water Supply

High-Density HDPE Pipe Durable High-Pressure Water Supply Polyethylene Tube s

75mm 90mm 110mm Polyethylene Hdpe Pipe Hdpe Pipes 1000mm 250mm

s Direct Injection Cement Pipe High-Density Polyethylene Corrugated Stainless Steel Pipe

HIGH QUALITY HDPE WATER SUPPLY PIPE

- Email: sales@pipesandfittings.net

- WeChat: +86 18337900677