LUOYANG DATANG ENERGY TECH CO.,LTD

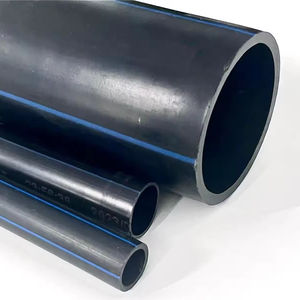

PE Tube High Density Polyethylene Pipe HDPE Pipe For Water Supply Hdpe Siphon Co-Layered Drainage Pipes

PRODUCT PARAMETERS

Description

Introduction of PE Tube High Density Polyethylene Pipe HDPE Pipe For Water Supply Hdpe Siphon Co-Layered Drainage Pipes

High Density Polyethylene Pipe (PE Pipe) is a durable and flexible thermoplastic piping solution widely used in industrial, municipal, agricultural, and mining applications. Known for its excellent chemical resistance, high impact strength, and long service life, PE pipes are ideal for transporting water, gases, and other fluids under varying pressure conditions.

Key Features of PE Tube High Density Polyethylene Pipe HDPE Pipe For Water Supply Hdpe Siphon Co-Layered Drainage Pipes

Corrosion & Chemical Resistance

Resistant to rust, scale, and most chemicals, making it suitable for aggressive environments.

Lightweight & Flexible

Easy to transport and install due to low weight; flexibility allows bending without joints in certain applications.

High Impact Strength

Withstands extreme weather conditions and physical stress, reducing breakage risks.

Leak-Free Joints

Heat-fused joints create seamless connections, minimizing leakage risks.

Long Service Life

UV-resistant and abrasion-proof, with a lifespan exceeding 50 years under proper conditions.

Smooth Inner Surface

Reduces friction loss, improving flow efficiency and lowering energy costs.

Eco-Friendly

Non-toxic, recyclable, and compliant with drinking water safety standards.

Cost-Effective

Lower installation and maintenance costs compared to traditional materials (e.g., metal, concrete).

(PE Tube High Density Polyethylene Pipe HDPE Pipe For Water Supply Hdpe Siphon Co-Layered Drainage Pipes)

Specifications of PE Tube High Density Polyethylene Pipe HDPE Pipe For Water Supply Hdpe Siphon Co-Layered Drainage Pipes

PE Tube High Thickness Polyethylene Pipeline is tough stuff. It handles water supply jobs perfectly. This pipe resists rust for life. Chemicals in dirt or water don’t hurt it. The material remains strong for several years underground. Installment is basic. The pipeline is surprisingly light. Employees relocate and connect areas conveniently. Its flexibility assists a great deal. The pipeline flexes around barriers without breaking. Ground motion or settling rarely damages it. Leaks are really not likely. Merged joints develop one continuous, sealed line. Water stays inside the pipe where it belongs.

HDPE Pipe for Water system is developed for pressure. It carries drinking water securely. The smooth inside surface is key. Water flows quick with less friction. Pumping costs drop gradually. You get constant stress throughout the system. This pipe fulfills strict wellness requirements. It keeps water tidy and pure. No damaging stuff seeps into the flow. Long-term dependability is outstanding. Maintenance needs are very little. Underground, it simply works year after year.

HDPE Siphon Co-Layered Drain Piping fix challenging water problems. They effectively move water from reduced locations. The unique co-layered structure is necessary. It integrates different material strengths. The result is a very sturdy siphon pipe. It deals with vacuum stress effectively. Water gets raised and relocated uphill dependably. These pipelines excel in water drainage applications. Utilize them for irrigation channels, land recovery, flooding control. They stand up to abrasion from sand or silt. The difficult outer layer shields against effect. Installment is quick utilizing typical HDPE methods.

(PE Tube High Density Polyethylene Pipe HDPE Pipe For Water Supply Hdpe Siphon Co-Layered Drainage Pipes)

Applications of PE Tube High Density Polyethylene Pipe HDPE Pipe For Water Supply Hdpe Siphon Co-Layered Drainage Pipes

HDPE pipelines are plastic pipelines made from solid polyethylene product. People pick them for numerous water system tasks. These pipelines handle water stress well. They do not damage conveniently. HDPE pipelines last a long period of time. They withstand corrosion and chemicals found in dirt and water. This makes them great for below ground pipelines lugging drinking water to homes and services. Cities utilize them for big water networks. Farms use them for watering systems. Manufacturing facilities use them for process water lines. You can connect them without numerous joints. This lowers the opportunity of leaks. Fewer leakages save water and money over time.

PE tube refers to smaller sized sizes of these pipes. Home builders frequently use it for shielding electrical wires or fiber optic wires underground. The tube shields the cables from water and damage. It’s versatile and challenging.

HDPE siphon pipelines are unique for water drainage. They move water efficiently, often using gravity siphon activity. This serves for draining pipes land, handling stormwater, or decreasing groundwater levels. They function well for agricultural areas, construction websites, and flooding control tasks. The co-layered design suggests some pipes have added layers. These layers include toughness for deep burial or high pressure. They assist the pipeline withstand squashing or fracturing. This split pipeline is superb for challenging drain tasks needing dependable circulation. Installing HDPE pipelines is normally straightforward. They can be found in long coils or straight lengths. Workers fuse sections together making use of warm. This develops very solid, leak-free connections. The material is light. This makes transport and taking care of less complicated than hefty metal pipelines. Utilizing HDPE pipelines decreases long-term expenses. They need much less upkeep. They do not wear away. Their long life implies less replacements.

Packing and Shipment

Depends on the products and qty,we could make the packing of coiling,rolls,bundle packing,crates or boxes,etc.

Shipment:By sea,railway,by air or as customer’s request.

Company Profile

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding HDPE Pipe Fitting, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net

Payment Terms

T/T,L/C at sight,Western Union & Paypal,etc.

5 FAQs of PE Tube High Density Polyethylene Pipe HDPE Pipe For Water Supply Hdpe Siphon Co-Layered Drainage Pipes

What are HDPE pipes?

HDPE pipes are plastic pipes. They are made from high-density polyethylene. This material is strong and flexible. These pipes carry water. They are used for drinking water supply. They are also used for drainage systems.

Why use HDPE pipes for water supply?

HDPE pipes are very good for water. They do not rust or corrode. Rust is a big problem with metal pipes. HDPE pipes stay clean inside. This keeps the water safe. They are also very smooth. Water flows easily through them. This saves energy.

What makes HDPE siphon co-layered pipes special?

These pipes have a special design. They are made with two layers. The inner layer is very smooth. This helps water flow fast. The outer layer is extra tough. This protects the pipe. This design is perfect for drainage. It handles suction forces well. It prevents collapse.

How are HDPE pipes joined together?

HDPE pipes connect without leaks. They use heat fusion. The pipe ends are heated. Then they are pressed together. They melt and become one piece. This makes the joint very strong. It is as strong as the pipe itself. There are no leaks. This is better than glue or rubber seals.

How long do HDPE pipes last?

HDPE pipes last a very long time. They can work for over 50 years. They resist chemicals in the soil. They handle temperature changes. They are not damaged by sunlight. They are tough against impacts. They do not break easily. This means less digging and repair. It saves money over time.

(PE Tube High Density Polyethylene Pipe HDPE Pipe For Water Supply Hdpe Siphon Co-Layered Drainage Pipes)

REQUEST A QUOTE

RELATED PRODUCTS

Hdpe Water Pipe s 3 Inch 63mm 2.5 Inch High Density 1.5Inch Poly Pe Fitting Pipe Irrigation Pipe

Durable 6mm HDPE High-Pressure Polyethylene Pipe for Agricultural Irrigation Water Drainage UV Stabilizers Long Service Flexible

High-Density HDPE Pipe Durable High-Pressure Water Supply Polyethylene Tube s

HDPE High Density Polyethylene PE100 Pipe Grade HDPE Plastic Raw Material HDPE Granules

Whole High Density Polyethylene HDPE Double Wall Corrugated Pipe Large Diameter Sewer Sewage

Factory PN 10 Hdpe Pipe 3 Inch Hdpe Corrugated Pipe

- Email: sales@pipesandfittings.net

- WeChat: +86 18337900677