LUOYANG DATANG ENERGY TECH CO.,LTD

PE Tube High Density Polyethylene Pipe HDPE Pipe For Water Supply Hdpe Siphon Co-Layered Drainage Pipes

PRODUCT PARAMETERS

Description

Introduction of PE Tube High Density Polyethylene Pipe HDPE Pipe For Water Supply Hdpe Siphon Co-Layered Drainage Pipes

High Density Polyethylene Pipe (PE Pipe) is a durable and flexible thermoplastic piping solution widely used in industrial, municipal, agricultural, and mining applications. Known for its excellent chemical resistance, high impact strength, and long service life, PE pipes are ideal for transporting water, gases, and other fluids under varying pressure conditions.

Key Features of PE Tube High Density Polyethylene Pipe HDPE Pipe For Water Supply Hdpe Siphon Co-Layered Drainage Pipes

Corrosion & Chemical Resistance

Resistant to rust, scale, and most chemicals, making it suitable for aggressive environments.

Lightweight & Flexible

Easy to transport and install due to low weight; flexibility allows bending without joints in certain applications.

High Impact Strength

Withstands extreme weather conditions and physical stress, reducing breakage risks.

Leak-Free Joints

Heat-fused joints create seamless connections, minimizing leakage risks.

Long Service Life

UV-resistant and abrasion-proof, with a lifespan exceeding 50 years under proper conditions.

Smooth Inner Surface

Reduces friction loss, improving flow efficiency and lowering energy costs.

Eco-Friendly

Non-toxic, recyclable, and compliant with drinking water safety standards.

Cost-Effective

Lower installation and maintenance costs compared to traditional materials (e.g., metal, concrete).

(PE Tube High Density Polyethylene Pipe HDPE Pipe For Water Supply Hdpe Siphon Co-Layered Drainage Pipes)

Specifications of PE Tube High Density Polyethylene Pipe HDPE Pipe For Water Supply Hdpe Siphon Co-Layered Drainage Pipes

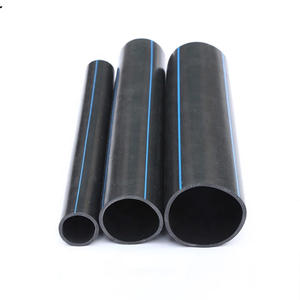

PE Tube High Thickness Polyethylene Pipe, referred to as HDPE pipeline, uses a modern-day option for water supply. HDPE material is solid and flexible. It withstands rust remarkably well. This pipeline lasts long, also in tough conditions. Water pipes made from HDPE are common. They transport alcohol consumption water securely. These pipelines deal with high stress accurately. Sizes range from little 20mm diameter to large 1200mm size. Stress rankings include PN6, PN8, PN10, PN12.5, PN16. This indicates various strengths for various requirements.

HDPE Siphon Co-Layered Drainage Piping are unique. They combine two layers into one pipeline. The internal layer is smooth for reliable water flow. The external layer supplies additional strength and strength. This layout is ideal for drainage systems requiring siphon activity. It prevents clogs efficiently. These pipelines execute well in various soil problems. They stand up to chemicals found underground.

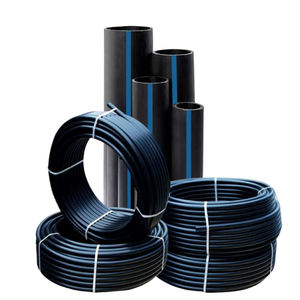

Both pipeline kinds share key advantages. Joints utilize warmth fusion welding. This develops watertight connections. The pipelines are really light contrasted to steel or concrete. Installation is much faster and more affordable. HDPE pipelines manage temperature levels from -60 ° C to 60 ° C. They are eco-friendly. Recycled material is frequently utilized in production. The pipelines resist cracking and abrasion. Upkeep costs remain reduced over years. They are suitable for trenchless installment approaches also. This minimizes surface disruption. Requirement sizes are generally 6 meters or 12 meters. Custom-made sizes are feasible. The pipeline wall density associates with the SDR score. Reduced SDR suggests thicker wall surfaces for greater pressure. Common shades are black with blue red stripes for water, black for drainage.

(PE Tube High Density Polyethylene Pipe HDPE Pipe For Water Supply Hdpe Siphon Co-Layered Drainage Pipes)

Applications of PE Tube High Density Polyethylene Pipe HDPE Pipe For Water Supply Hdpe Siphon Co-Layered Drainage Pipes

High Thickness Polyethylene pipelines, called HDPE pipes, are tough plastic tubes. They handle water system and water drainage jobs well. These pipelines resist corrosion and chemicals. They last a very long time without damaging down. HDPE pipes remain strong even below ground. They flex quickly around barriers. This makes installment quick and low-cost. Workers conserve money and time.

For water system systems, HDPE pipes are safe. They lug drinking water without adding bad tastes or smells. The pipelines collaborate securely with warm combination. This stops leakages far better than old pipelines. No water obtains lost. Pressure stays stable. Cities and communities use them for major lines and home links.

HDPE siphon pipes move water effectively. Their smooth inside allows water flow quick with much less energy. Siphons work uphill or downhill without extra pumps. This reduces electrical power prices. Farmers utilize them for irrigation. Manufacturing facilities use them for relocating procedure water.

Co-layered drainage pipes have additional toughness. They integrate HDPE layers for hefty loads and hard soils. These pipelines handle dirty water, chemicals, and waste without damages. They will not split under roads or structures. Storm drains and sewer systems rely upon them.

These pipes operate in tough areas. Hot or cold weather doesn’t damage them. Earthquakes or ground changes hardly ever break them. Repair demands decrease. Upkeep expenses remain reduced. HDPE pipelines are environment-friendly also. They use less power to make. Old pipes get reused into new ones.

Select HDPE pipes for reliable water networks. They outmatch steel or concrete pipelines. Projects complete quicker. Systems run smoother for years. Water remains tidy. Drainage moves without obstructions.

Packing and Shipment

Depends on the products and qty,we could make the packing of coiling,rolls,bundle packing,crates or boxes,etc.

Shipment:By sea,railway,by air or as customer’s request.

Company Profile

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding HDPE Pipe Fitting, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net

Payment Terms

T/T,L/C at sight,Western Union & Paypal,etc.

5 FAQs of PE Tube High Density Polyethylene Pipe HDPE Pipe For Water Supply Hdpe Siphon Co-Layered Drainage Pipes

PE Tube HDPE Pipe FAQs

What makes HDPE pipe good for water supply?

HDPE pipe is made from strong plastic. It bends easily without breaking. This flexibility helps during installation. It handles ground movement well. The material resists rust and chemical damage. It keeps water clean and safe. HDPE pipes last a long time underground.

What pressure can HDPE pipes handle?

HDPE pipes come in different pressure ratings. These are called PN classes like PN10 or PN16. The PN number tells you the pressure capacity. PN10 handles 10 bar pressure. PN16 handles 16 bar pressure. Choose the PN class based on your project’s needs. The pipe wall thickness depends on the PN class and pipe size.

How do you install HDPE pipes?

Installation is flexible. You can use traditional open-trench methods. HDPE pipe sections fuse together using heat. This creates strong, permanent, leak-proof joints. You can also use trenchless methods. Directional drilling pulls long lengths of fused pipe underground. This minimizes surface disruption. HDPE’s flexibility makes these methods possible.

Why are HDPE pipes durable?

HDPE material is tough. It withstands impact better than many materials. It doesn’t corrode like metal pipes. Chemicals in soil or water won’t easily damage it. The fused joints are as strong as the pipe itself. This prevents leaks at connection points. HDPE pipes resist cracking and abrasion. They perform well for decades.

Where are siphon co-layered HDPE pipes used?

Siphon co-layered pipes are special HDPE pipes. They have two bonded layers. The inner layer is smooth for good flow. The outer layer is tough for protection. These pipes are mainly for drainage systems. They work well in siphon applications. Siphons move water over obstacles. They are also used for stormwater systems, culverts, and land drainage projects. The dual-layer design gives strength and flow efficiency.

(PE Tube High Density Polyethylene Pipe HDPE Pipe For Water Supply Hdpe Siphon Co-Layered Drainage Pipes)

REQUEST A QUOTE

RELATED PRODUCTS

Irrigation Pipe System Garden Drip Water Timer Polyethylene HDPE Pipe s Pe100 Pe Hd Pipe Tube

Hdpe High Density Polyethylene Extrusion Molding HHM TR480AT Hdpe Granules Pipe Grade Virgin HDPE Plastic Raw Materials

High Density Polyethylene 50-200mm Corrugated Permeable Drain Pipe HDPE Hard Permeable Pipe

HDPE PE100 High Density Polyethylene Floating Water Mud Slurry Sand Gas Oil Dredging Dredge Dredger Mining Supply Plastic Pipe

Stock Goods HDPE YGH041 Plastic Raw Material Virgin HDPE Granules Pipe Grade High Density Polyethylene Resin

Factory High Density Polyethylene Petutup Hujung Tuberia Hdpe Pipe 90mm Irrigation Coiled 1 Inch Drain Poly Pipe

- Email: sales@pipesandfittings.net

- WeChat: +86 18337900677