LUOYANG DATANG ENERGY TECH CO.,LTD

Recycle HDPE Pipe Extrusion Grade High Density Polyethylene Plastic Raw Material

PRODUCT PARAMETERS

Description

Introduction of Recycle HDPE Pipe Extrusion Grade High Density Polyethylene Plastic Raw Material

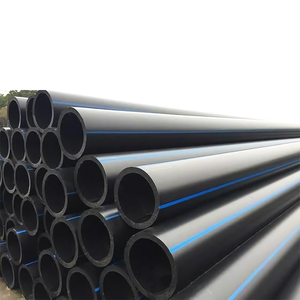

High Density Polyethylene Pipe (PE Pipe) is a durable and flexible thermoplastic piping solution widely used in industrial, municipal, agricultural, and mining applications. Known for its excellent chemical resistance, high impact strength, and long service life, PE pipes are ideal for transporting water, gases, and other fluids under varying pressure conditions.

Key Features of Recycle HDPE Pipe Extrusion Grade High Density Polyethylene Plastic Raw Material

Corrosion & Chemical Resistance

Resistant to rust, scale, and most chemicals, making it suitable for aggressive environments.

Lightweight & Flexible

Easy to transport and install due to low weight; flexibility allows bending without joints in certain applications.

High Impact Strength

Withstands extreme weather conditions and physical stress, reducing breakage risks.

Leak-Free Joints

Heat-fused joints create seamless connections, minimizing leakage risks.

Long Service Life

UV-resistant and abrasion-proof, with a lifespan exceeding 50 years under proper conditions.

Smooth Inner Surface

Reduces friction loss, improving flow efficiency and lowering energy costs.

Eco-Friendly

Non-toxic, recyclable, and compliant with drinking water safety standards.

Cost-Effective

Lower installation and maintenance costs compared to traditional materials (e.g., metal, concrete).

(Recycle HDPE Pipe Extrusion Grade High Density Polyethylene Plastic Raw Material)

Specifications of Recycle HDPE Pipe Extrusion Grade High Density Polyethylene Plastic Raw Material

This recycled HDPE pipeline extrusion grade product provides dependable efficiency for pipeline manufacturing. It fulfills strict specifications ensuring solid pipes. The Melt Flow Index (MFI) typically drops in between 0.3 and 0.8 g/10 min. This MFI range is essential. It supplies the right thaw thickness during extrusion. Great circulation avoids problems like thaw fracture. It additionally guarantees outstanding weldability for pipe joints. Density actions around 0.950 to 0.955 g/cm FIVE. This high density provides the last pipe excellent rigidity. It also offers needed resistance to ecological stress and anxiety breaking.

The material offers high tensile strength. It keeps excellent effect resistance as well. This strength is important. Pipelines should manage installation stresses and ground stress. UV stabilizers are added. These shield the pipelines from sunshine degradation. This makes certain long life span outdoors. The color consistency is regulated batch to set. This provides consistent look in the completed pipeline item. The recycled material percentage is plainly defined. It satisfies industry criteria for lasting materials.

Quality control is strenuous. Every batch undergoes detailed screening. Tests confirm MFI, thickness, and mechanical residential properties. This ensures the product does as expected in your extrusion line. Thermal security is excellent. It protects against deterioration during high-temperature processing. The material follows pertinent global criteria. These include ISO and water contact qualifications like WRAS. This makes it ideal for stress pipelines and safe and clean water applications. It processes smoothly on typical HDPE pipeline extrusion lines. Operators discover it regular and reliable.

(Recycle HDPE Pipe Extrusion Grade High Density Polyethylene Plastic Raw Material)

Applications of Recycle HDPE Pipe Extrusion Grade High Density Polyethylene Plastic Raw Material

Recycled HDPE pipeline extrusion grade plastic is a high-grade product. Producers make it from utilized high-density polyethylene products. This material gets processed right into small plastic pellets. Factories make use of these pellets to make solid new pipes. The procedure works well for lots of pipeline types. Pipes are a major usage. This product handles water circulation safely. It stands up to rust and chemicals common in water systems. Gas pipes additionally use this recycled HDPE. Security is crucial below. The product offers good stamina and leakage resistance. Mining procedures need tough pipelines. Recycled HDPE pipelines function underground. They deal with abrasion and harsh chemicals. Industrial factories use these pipelines also. They lug numerous liquids and waste materials safely. Agricultural irrigation benefits greatly. Farmers lay long runs of HDPE pipeline. It’s lightweight for simple handling. The material holds up against sunlight and weather condition. Sewage system and drainage systems are another large location. Recycled HDPE pipes take care of waste circulation efficiently. They withstand corrosion from sewage. Landfill applications make use of these pipes for leachate collection. They have dangerous liquids successfully. The material offers excellent price savings. Using recycled plastic reduces resources expenses. It executes nearly fresh HDPE pipe product. Toughness is a significant advantage. These pipes last years without damaging down. They stand up to influences and cracks well. Setup is frequently less complex than metal pipes. The pipelines can be integrated with each other easily. This develops really solid, leak-free joints. Ecological advantages are clear. Using recycled plastic decreases land fill waste. It lessens the requirement for new oil-based plastic manufacturing. This conserves power and resources overall. Recycled HDPE pipeline product fulfills strict industry requirements. It ensures dependable performance throughout various requiring applications.

Packing and Shipment

Depends on the products and qty,we could make the packing of coiling,rolls,bundle packing,crates or boxes,etc.

Shipment:By sea,railway,by air or as customer’s request.

Company Profile

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding HDPE Pipe Fitting, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net

Payment Terms

T/T,L/C at sight,Western Union & Paypal,etc.

5 FAQs of Recycle HDPE Pipe Extrusion Grade High Density Polyethylene Plastic Raw Material

Recycle HDPE Pipe Extrusion Grade High Density Polyethylene Plastic Raw Material is a popular choice. Here are 5 common questions.

What is this material exactly? It’s recycled plastic pellets. They come from used HDPE products. These pellets are processed for pipe manufacturing. They meet strict quality standards for extrusion.

What are its main properties? This material is very strong. It handles high pressure well. It resists chemicals and corrosion. It stays flexible in cold weather. It doesn’t crack easily. These traits make pipes last long.

Where can you use it? It’s ideal for water pipes. It works for drainage systems too. You find it in irrigation projects. Gas distribution lines use it. Industrial fluid transport needs it. Mines and construction sites rely on it.

How does it compare to new HDPE? Recycled HDPE performs almost the same. It has similar strength and flexibility. Color might be less consistent. It costs less than virgin material. It meets industry requirements for pipes. Testing ensures reliability.

Why choose recycled over new? It reduces plastic waste. Less new plastic gets made. This saves energy. It cuts carbon emissions. It lowers environmental impact. Using recycled material supports sustainability goals.

(Recycle HDPE Pipe Extrusion Grade High Density Polyethylene Plastic Raw Material)

REQUEST A QUOTE

RELATED PRODUCTS

High Density Polyethylene HDPE SDR17 Pipe in Various Lengths Custom Processing Service Available

High Quality HDPE 200mm-2000mm PE Double Wall Corrugated Pipe with Smooth Surface Durable Sealing Ring Socket Connection

High-Density Polyethylene (HDPE) Pipe SDR Made From PE Material

HDPE PE100 High Density P6006 Polyethylene HE3490 Resin Raw Material Virgin HDPE Pipe Granules

HDPE High-Density Polyethylene Water Supply Pipe High Quality High Pressure for Drip Irrigation System Kit

Stock Goods HDPE YGH041 Plastic Raw Material Virgin HDPE Granules Pipe Grade High Density Polyethylene Resin

- Email: sales@pipesandfittings.net

- WeChat: +86 18337900677