LUOYANG DATANG ENERGY TECH CO.,LTD

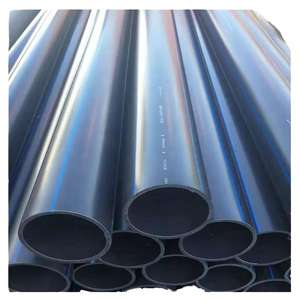

Recycle HDPE Pipe Extrusion Grade High Density Polyethylene Plastic Raw Material

PRODUCT PARAMETERS

Description

Introduction of Recycle HDPE Pipe Extrusion Grade High Density Polyethylene Plastic Raw Material

High Density Polyethylene Pipe (PE Pipe) is a durable and flexible thermoplastic piping solution widely used in industrial, municipal, agricultural, and mining applications. Known for its excellent chemical resistance, high impact strength, and long service life, PE pipes are ideal for transporting water, gases, and other fluids under varying pressure conditions.

Key Features of Recycle HDPE Pipe Extrusion Grade High Density Polyethylene Plastic Raw Material

Corrosion & Chemical Resistance

Resistant to rust, scale, and most chemicals, making it suitable for aggressive environments.

Lightweight & Flexible

Easy to transport and install due to low weight; flexibility allows bending without joints in certain applications.

High Impact Strength

Withstands extreme weather conditions and physical stress, reducing breakage risks.

Leak-Free Joints

Heat-fused joints create seamless connections, minimizing leakage risks.

Long Service Life

UV-resistant and abrasion-proof, with a lifespan exceeding 50 years under proper conditions.

Smooth Inner Surface

Reduces friction loss, improving flow efficiency and lowering energy costs.

Eco-Friendly

Non-toxic, recyclable, and compliant with drinking water safety standards.

Cost-Effective

Lower installation and maintenance costs compared to traditional materials (e.g., metal, concrete).

(Recycle HDPE Pipe Extrusion Grade High Density Polyethylene Plastic Raw Material)

Specifications of Recycle HDPE Pipe Extrusion Grade High Density Polyethylene Plastic Raw Material

This recycled HDPE pipe extrusion quality resources offers reputable performance for pipeline production. It comes from very carefully refined post-consumer or post-industrial high-density polyethylene. This product provides the necessary residential or commercial properties needed for solid, resilient pipelines. The thaw flow rate (MFR) is managed firmly. Constant MFR guarantees smooth extrusion processing. It protects against issues like rising throughout production. Good flow is vital for consistent pipeline walls.

Density drops within the common range for HDPE pipe grades. Proper thickness offers the necessary rigidity and stress resistance for pipes. The product shows superb environmental stress fracture resistance (ESCR). High ESCR is vital for buried pipeline applications. It withstands dirt tensions and chemicals over years. The raw material possesses excellent tensile strength. This toughness aids pipes take care of interior stress and external tons.

We process this recycled HDPE to remove pollutants completely. Effective cleansing guarantees purity and consistent efficiency. The compound shows solid resistance to many chemicals. This resistance is essential for drain and industrial pipelines. It stands up against common corrosive substances. The product refines well on standard single-screw extruders. Reputable processing minimizes downtime and waste. Color consistency is managed for normal pipeline applications. All-natural or black substances prevail options. This recycled quality satisfies key specifications for non-pressure and specific stress pipeline makes use of. It gives a lasting solution without compromising pipeline high quality. Manufacturers acquire a reliable, environmentally friendly raw material source.

(Recycle HDPE Pipe Extrusion Grade High Density Polyethylene Plastic Raw Material)

Applications of Recycle HDPE Pipe Extrusion Grade High Density Polyethylene Plastic Raw Material

This recycled HDPE pipeline extrusion quality material is made from recycled high-density polyethylene plastic. It gets processed into pellets prepared for pipeline manufacturing. Manufacturers make use of these pellets in typical extrusion devices. This creates strong, long lasting pipes for numerous uses. Recycled HDPE pipelines manage water circulation well. They resist rust and chemicals. This makes them secure for alcohol consumption water systems. Towns mount them for primary lines and service links. These pipes benefit wastewater systems too. They take care of sewer and stormwater properly. Their smooth inside avoids accumulation and clogs. Recycled HDPE pipes are good for farming watering. Farmers lay them across fields for drip systems or lawn sprinklers. They endure sunlight and weather condition. Industrial centers use these pipelines commonly. They move numerous process fluids and chemicals safely. The product stands up to several severe materials. Mining operations count on recycled HDPE pipelines. They relocate slurry, tailings, and seeping services. Abrasion resistance is a key advantage right here. Gas circulation networks utilize details qualities of these pipelines. They securely bring gas at reduced pressures. Recycled HDPE pipes are lightweight. This makes them much easier to transfer and install. Workers handle them without heavy machinery. They save substantial labor costs. Joining areas is simple making use of warmth blend. This produces leak-proof, monolithic joints. The pipes are extremely flexible. They flex slightly without damaging. This helps throughout installment around barriers. Ground movement creates less damage. Recycled HDPE pipes last years underground. They don’t corrosion or rot. Maintenance demands are low. Using recycled material reduces environmental impact. It draws away plastic waste from garbage dumps. It lowers the carbon footprint of pipe manufacturing. This provides an economical remedy. Efficiency matches virgin HDPE pipeline in the majority of applications. It gives trusted service.

Packing and Shipment

Depends on the products and qty,we could make the packing of coiling,rolls,bundle packing,crates or boxes,etc.

Shipment:By sea,railway,by air or as customer’s request.

Company Profile

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding HDPE Pipe Fitting, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net

Payment Terms

T/T,L/C at sight,Western Union & Paypal,etc.

5 FAQs of Recycle HDPE Pipe Extrusion Grade High Density Polyethylene Plastic Raw Material

What is Recycle HDPE Pipe Extrusion Grade? This material is recycled high-density polyethylene plastic. It comes from used HDPE products. The recycling process cleans and melts the plastic. Then it forms uniform pellets. These pellets are for making pipes. They meet extrusion requirements. They have consistent melt flow. They ensure pipe strength and durability.

Where is this recycled HDPE used? It is for manufacturing pipes. Common applications include water supply lines. Also drainage systems and gas pipes. Agricultural irrigation pipes too. Industrial fluid transport pipes. The material handles pressure well. It resists chemicals and corrosion. It works in tough environments.

How does it compare to virgin HDPE? Recycled HDPE performs similarly in pipes. But properties depend on the source material. Quality control ensures reliability. It meets industry standards. It costs less than virgin plastic. It offers a budget-friendly option. Performance is proven in tests.

What environmental benefits does it offer? Using recycled HDPE reduces landfill waste. It saves energy during production. It lowers carbon emissions. It conserves petroleum resources. It supports circular economy goals. Every ton recycled helps the planet.

How should this material be stored? Keep it in a dry place. Avoid direct sunlight. Moisture damages the pellets. Use sealed containers. Follow first-in-first-out stock rotation. Handle with clean equipment. Prevent contamination from other materials. Proper storage maintains quality.

(Recycle HDPE Pipe Extrusion Grade High Density Polyethylene Plastic Raw Material)

REQUEST A QUOTE

RELATED PRODUCTS

Pn10 Pn16 HDPE Tube Large Diameter 110mm-280mm PE100 Plastic Tubing For Garden Hotel High-Density Polyethylene (HDPE) Pipe

High Density HDPE PE100 Large Diameter Polyethylene Pipe For Water Supply

High Quality Plastic Pipe 5 6 8 10 Inch Diameter Pvc Water Pipe 300mm 600mm Water Upvc Pipe Size

HDPE Flexible Construction Plastic Tubes High Pressure Underground Water Supply Industrial Pressure System Drainage Tubing 6mm

Marine High Density HDPE Plastic Dredging Pipe Floater Float Sand Discharge Dredging Pipeline Buoy Plastic Pipe Floater

High Density Polyethylene Pipes Hdpe 4 Inch 5 Inch 6 Inch PE100 Hdpe Pipes Hdpe Water Pipe

- Email: sales@pipesandfittings.net

- WeChat: +86 18337900677