LUOYANG DATANG ENERGY TECH CO.,LTD

Whole High Density Polyethylene HDPE Double Wall Corrugated Pipe Large Diameter Sewer Sewage

PRODUCT PARAMETERS

Description

Introduction of Whole High Density Polyethylene HDPE Double Wall Corrugated Pipe Large Diameter Sewer Sewage

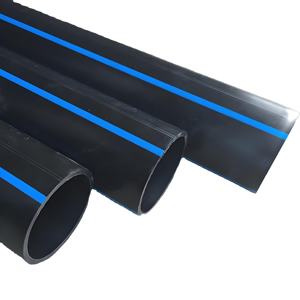

High Density Polyethylene Pipe (PE Pipe) is a durable and flexible thermoplastic piping solution widely used in industrial, municipal, agricultural, and mining applications. Known for its excellent chemical resistance, high impact strength, and long service life, PE pipes are ideal for transporting water, gases, and other fluids under varying pressure conditions.

Key Features of Whole High Density Polyethylene HDPE Double Wall Corrugated Pipe Large Diameter Sewer Sewage

Corrosion & Chemical Resistance

Resistant to rust, scale, and most chemicals, making it suitable for aggressive environments.

Lightweight & Flexible

Easy to transport and install due to low weight; flexibility allows bending without joints in certain applications.

High Impact Strength

Withstands extreme weather conditions and physical stress, reducing breakage risks.

Leak-Free Joints

Heat-fused joints create seamless connections, minimizing leakage risks.

Long Service Life

UV-resistant and abrasion-proof, with a lifespan exceeding 50 years under proper conditions.

Smooth Inner Surface

Reduces friction loss, improving flow efficiency and lowering energy costs.

Eco-Friendly

Non-toxic, recyclable, and compliant with drinking water safety standards.

Cost-Effective

Lower installation and maintenance costs compared to traditional materials (e.g., metal, concrete).

(Whole High Density Polyethylene HDPE Double Wall Corrugated Pipe Large Diameter Sewer Sewage)

Specifications of Whole High Density Polyethylene HDPE Double Wall Corrugated Pipe Large Diameter Sewer Sewage

These large diameter sewage system pipes use high thickness polyethylene. HDPE makes them solid and versatile. They manage hefty loads well. Underground stress will not squash them conveniently. HDPE also withstands chemicals. Sewage acids and alkalis won’t eat away at the pipeline walls. Corrosion and corrosion are impossible. This product lasts a long time.

The pipe has a dual wall design. The outside wall has bumpy ridges. This corrugation adds toughness. It aids spread out ground stress uniformly. The within wall is totally smooth. This smooth surface allows sewage flow openly. Solids will not catch or accumulate easily. Blockages happen less frequently. The two walls collaborate. They make the pipe lightweight yet very difficult.

These pipelines can be found in big sizes. Sizes typically begin around 18 inches. They go up to 60 inches or even larger. Large pipelines relocate big sewage quantities effectively. They suit major trunk lines and interceptors. Larger projects require bigger pipes.

Installment is straightforward. The pipelines are lighter than concrete or metal pipes. Workers handle them less complicated. They attach using straightforward gaskets or warm blend. Gaskets create water tight seals swiftly. Heat combination thaws completions with each other. This makes a joint as solid as the pipeline itself. Leakages at joints are unusual. The pipelines adjust to small ground changes. They bend a little without breaking. This flexibility prevents fractures.

These pipes are developed for demanding jobs. They work in community sewer systems. They take care of stormwater drain. Industrial wastewater lines use them too. Landfills utilize them for leachate collection. Anywhere large quantities flow underground, these pipes do. They give reputable, durable flow.

(Whole High Density Polyethylene HDPE Double Wall Corrugated Pipe Large Diameter Sewer Sewage)

Applications of Whole High Density Polyethylene HDPE Double Wall Corrugated Pipe Large Diameter Sewer Sewage

Big size HDPE double wall surface corrugated pipeline is developed difficult for demanding sewage system and sewage tasks. Its special structure gives it huge benefits. The outer wall is corrugated. This corrugation makes the pipeline unbelievably strong. It manages hefty loads from soil and website traffic conveniently. This stamina is important under roads and in deep trenches. The internal wall surface is flawlessly smooth. This level of smoothness maintains sewage moving fast. It protects against buildup and clogs. This pipeline doesn’t require frequent cleansing.

HDPE product itself is a big plus. It makes fun of corrosion. Severe chemicals in sewer will not gnaw at it. This lasts years longer than old concrete or steel pipelines. It stays leak-proof. The integrated joints create a constant seal underground. This keeps sewage in the pipe. It keeps groundwater out. Protecting the setting issues. This pipeline assists do that.

Cities rely upon this pipeline for significant sewage system trunk lines. It moves huge quantities of wastewater reliably. Industrial plants utilize it too. Manufacturing facilities require resilient pipelines for their process water and waste. The pipe manages difficult commercial flows without failing. Stormwater systems benefit as well. Large culverts and drain networks require strength and circulation. This pipe supplies both. It makes it through hefty runoff and particles.

Installation staffs like it. The pipeline is remarkably light for its size. This makes carrying and positioning areas much easier. It saves time and labor costs. The adaptability aids as well. It bends somewhat to follow the trench course. This stays clear of requiring extra fittings at every turn. Connections are simple. Butt blend welding melts the pipeline ends with each other. This develops joints as solid as the pipe itself. No weak points.

The outcome is a resilient, effective system. It decreases upkeep migraines. It reduces the total cost over years. Towns and contractors select it for critical sewage framework. It simply does much better underground.

Packing and Shipment

Depends on the products and qty,we could make the packing of coiling,rolls,bundle packing,crates or boxes,etc.

Shipment:By sea,railway,by air or as customer’s request.

Company Profile

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding HDPE Pipe Fitting, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net

Payment Terms

T/T,L/C at sight,Western Union & Paypal,etc.

5 FAQs of Whole High Density Polyethylene HDPE Double Wall Corrugated Pipe Large Diameter Sewer Sewage

What is HDPE double wall corrugated pipe? This pipe is made from high-density polyethylene. It has two walls. The outer wall is corrugated for strength. The inner wall is smooth for easy flow. This design makes the pipe strong. It works well for sewer systems.

Why choose HDPE for large diameter sewer pipes? HDPE is a tough plastic. It resists rust and chemicals. It lasts a long time. HDPE pipes are lightweight. They are easier to handle than concrete or metal pipes. They do not leak easily. This protects the environment.

How does the double wall structure help the pipe? The double wall gives extra strength. The corrugated outer wall adds stiffness. The smooth inner wall lets waste flow freely. The pipe bends a little without breaking. This is good in shifting soil. It handles heavy loads from above ground.

What sizes are available for these pipes? These pipes come in large diameters. Common sizes start at 18 inches. They go up to 60 inches. Other sizes are available too. Custom sizes can be made if needed. This fits different project needs.

How are these pipes installed? Workers connect pipes using couplings or heat fusion. Heat fusion melts the pipe ends. Then they join them. This makes a permanent seal. Workers lay the pipes in a trench. Then they cover them with soil. This method is fast. It saves money. Proper installation keeps the system reliable.

(Whole High Density Polyethylene HDPE Double Wall Corrugated Pipe Large Diameter Sewer Sewage)

REQUEST A QUOTE

RELATED PRODUCTS

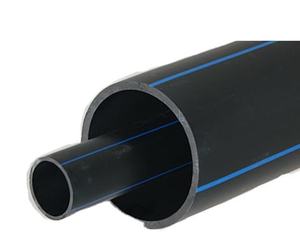

High Pressure HDPE Pipe for Water Supply Irrigation Agriculture Flexible Underground Drainage Roll-Industrial Construction

High Density HDPE PE100 Large Diameter Polyethylene Pipe For Water Supply

Water and Wastewater High Density Polyethylene Pipe

High Density Polyethylene HDPE Pipe 4 Inch 5 Inch 6 Inch PE100 Water Pipe Corrosion Resistant High Pressure Non-Toxic Anti-UV

Factory PN 10 Hdpe Pipe 3 Inch Hdpe Corrugated Pipe

HDPE Flexible Construction Plastic Tubes High Pressure Underground Water Supply Industrial Pressure System Drainage Tubing 6mm

- Email: sales@pipesandfittings.net

- WeChat: +86 18337900677