LUOYANG DATANG ENERGY TECH CO.,LTD

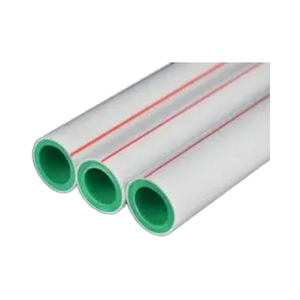

High Quality Polypropylene Pipe Ppr Pipe Fusion Type 4m Ppr Pipes

PRODUCT PARAMETERS

Description

Introduction of High Quality Polypropylene Pipe Ppr Pipe Fusion Type 4m Ppr Pipes

PPR pipe (full name Polypropylene Random Copolymer Pipe, is a high-performance plastic pipe made of high-quality random copolymer polypropylene raw materials. Due to its high temperature resistance, pressure resistance, environmental protection and non-toxicity, it is widely used in building hot and cold water systems, HVAC engineering, drinking water transportation and industrial fluid transmission, and is an ideal substitute for traditional metal pipes.

Characteristics and Features of High Quality Polypropylene Pipe Ppr Pipe Fusion Type 4m Ppr Pipes

High temperature and high pressure resistance

Long-term working temperature can reach 70°C, short-term high temperature resistance to 95°C, excellent pressure bearing performance (common pressure level PN20, PN25).

Environmental protection and health

The raw materials are pure and non-toxic, meet drinking water standards (such as FDA, EN ISO and other certifications), do not breed bacteria, and ensure the safety of water quality.

Corrosion and anti-scaling

Acid and alkali resistance, strong chemical corrosion resistance, smooth inner wall, not easy to scale, long-term use of stable flow.

Hot melt connection, strong sealing

Adopting hot melt socket technology, there is no risk of leakage at the connection, and the integrated structure improves system reliability.

Lightweight and easy to construct

The weight is only 1/8 of that of metal pipes, which is convenient for transportation and installation, reducing labor costs.

Long life and low maintenance

The designed service life is more than 50 years, maintenance-free, and the overall cost is low.

Energy-saving and heat preservation

The thermal conductivity is low (only 1/200 of metal pipes), which reduces heat loss and is suitable for hot water systems.

(High Quality Polypropylene Pipe Ppr Pipe Fusion Type 4m Ppr Pipes)

Specifications of High Quality Polypropylene Pipe Ppr Pipe Fusion Type 4m Ppr Pipes

High quality polypropylene pipe, known as PPR pipe, offers excellent performance for plumbing and heating systems. This pipe uses polypropylene random copolymer material. This material gives the pipe great strength and long life. It resists heat very well. It handles hot and cold water perfectly. The standard length is 4 meters. This length suits many installation needs. It reduces joints in straight runs. Fewer joints mean fewer possible leak points.

The fusion type connection is a key feature. Installers use heat to join sections. Heat melts the pipe and fitting ends together. They fuse into one solid piece. This creates a permanent, leak-proof seal. The joint becomes as strong as the pipe itself. This method is reliable. It avoids the problems of glues or threaded connections. Fusion welding is efficient. Trained plumbers work fast with the right tools.

These pipes handle high temperatures. They work safely with water up to 95 degrees Celsius. They also manage high water pressure. The pipe walls are smooth inside. Smooth walls mean less friction. Water flows easily. This saves energy over time. Mineral deposits don’t build up easily. This keeps water clean and flow strong. PPR resists chemical corrosion. It won’t rust or corrode like metal pipes. This makes it ideal for many water types. It works well for drinking water systems. It also suits heating circuits and industrial uses.

Different sizes are available. Common diameters range from 20mm to 110mm. This covers home plumbing to larger building projects. The pipes are light. This makes them easy to transport and handle on site. Cutting them is simple. Installation is generally quicker than with metal pipes. PPR pipes are quiet. They don’t transmit water hammer noise like metal can. They are a cost-effective solution. Their long service life reduces replacement costs. They need little maintenance once installed correctly. These pipes provide a dependable solution for modern water systems. They ensure safe, clean water delivery for many years. Builders and plumbers trust them for reliable performance.

(High Quality Polypropylene Pipe Ppr Pipe Fusion Type 4m Ppr Pipes)

Applications of High Quality Polypropylene Pipe Ppr Pipe Fusion Type 4m Ppr Pipes

High quality PPR pipes made from polypropylene solve many plumbing and industrial needs. Their fusion welding method creates strong, permanent joints. This stops leaks before they start. Installers heat the pipe and fitting ends together using a special tool. The heated material melts slightly. They press the melted ends together. The material cools and fuses into one solid piece. This creates a joint as strong as the pipe itself. It is very reliable over time.

These PPR pipes handle hot and cold water systems perfectly. They resist corrosion and chemical damage. You won’t find rust or scale building up inside them. This keeps water clean and flowing smoothly for years. The material handles high temperatures well. It carries hot water safely without warping or weakening. It also withstands high water pressure inside the system. This durability makes PPR pipes ideal for demanding applications.

Builders and engineers choose these pipes for many projects. They work great in homes for drinking water lines and heating systems. Factories use them for moving chemicals and compressed air. Farms rely on them for irrigation systems. Hospitals install them for sanitary water distribution. The 4 meter length is a practical size. It reduces the number of joints needed in long runs. This saves installation time and lowers the risk of potential leaks. Workers cut the pipes easily to fit specific spaces.

The material stays tough in cold weather too. It doesn’t become brittle. This is important for outdoor pipes or in unheated buildings. PPR pipes are lightweight. This makes them easier to transport and handle on site compared to metal pipes. Their smooth inner surface minimizes friction loss. Water flows efficiently, saving energy for pumping systems. They offer a long service life with minimal maintenance required.

Packing and Shipment

Depends on the products and qty,we could make the packing of coiling,rolls,bundle packing,crates or boxes,etc.

Shipment:By sea,railway,by air or as customer’s request.

Company Profile

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding HDPE Pipe Fitting, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net

Payment Terms

T/T,L/C at sight,Western Union & Paypal,etc.

5 FAQs of High Quality Polypropylene Pipe Ppr Pipe Fusion Type 4m Ppr Pipes

FAQs: High Quality Polypropylene Pipe (PPR Pipe Fusion Type, 4m Lengths)

What makes PPR pipe material safe?

PPR pipes use polypropylene random copolymer. This material is food-grade safe. It doesn’t add bad tastes or smells to water. It meets strict standards for drinking water systems. Chemicals won’t leach into the water supply. This ensures clean water delivery.

How long do PPR pipes last?

PPR pipes last decades. They resist corrosion extremely well. Chemicals won’t eat away at the pipe walls. They handle high heat without deforming. The material doesn’t break down easily. Properly installed, expect over 50 years of reliable service.

Why use fusion welding for PPR pipes?

Fusion welding creates the strongest joints. It melts the pipe and fitting ends together. They fuse into one solid piece of plastic. This eliminates leaks at connection points. The joint becomes as strong as the pipe itself. It’s the most reliable method for PPR.

Is the 4-meter length standard?

Yes, 4 meters is the standard factory length. It’s common worldwide. This length balances ease of handling with efficiency. Longer pipes reduce the number of joints needed. It works well for most residential and commercial plumbing runs.

Where are PPR pipes commonly used?

PPR pipes suit many applications. They work perfectly for hot and cold water lines inside buildings. They are ideal for central heating systems. They handle compressed air lines well. They are used for food and beverage processing lines. They are also good for certain chemical transport.

(High Quality Polypropylene Pipe Ppr Pipe Fusion Type 4m Ppr Pipes)

REQUEST A QUOTE

RELATED PRODUCTS

Random Copolymer Polypropylene Plastic Raw Material PP Pellets Pipe Grade

High Pressure Ppr Pipe and Fittings Plumbing Materials Polypropylene Pipe PN25

PP Random Copolymer Granule Polypropylene Plastic for Cold and Hot Water Pipe

Factory s 3-layer Polypropylene Random Pipe for Drinking Water Supply PP-R Meter Scale

ISO GB Compliant PPR Plastic Pipe Hot Cold Water DIN Flexible Joint Tube

Wholesale PN16 PN20 PN25 PPR Pipe

- Email: sales@pipesandfittings.net

- WeChat: +86 18337900677