LUOYANG DATANG ENERGY TECH CO.,LTD

Plastic Water Poly HDPE Pipe Supply

PRODUCT PARAMETERS

Description

Introduction of Plastic Water Poly HDPE Pipe Supply

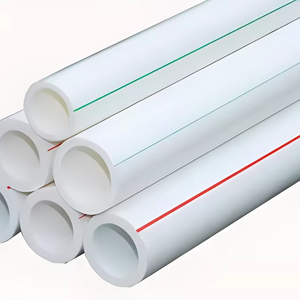

PPR pipe (full name Polypropylene Random Copolymer Pipe, is a high-performance plastic pipe made of high-quality random copolymer polypropylene raw materials. Due to its high temperature resistance, pressure resistance, environmental protection and non-toxicity, it is widely used in building hot and cold water systems, HVAC engineering, drinking water transportation and industrial fluid transmission, and is an ideal substitute for traditional metal pipes.

Characteristics and Features of Plastic Water Poly HDPE Pipe Supply

High temperature and high pressure resistance

Long-term working temperature can reach 70°C, short-term high temperature resistance to 95°C, excellent pressure bearing performance (common pressure level PN20, PN25).

Environmental protection and health

The raw materials are pure and non-toxic, meet drinking water standards (such as FDA, EN ISO and other certifications), do not breed bacteria, and ensure the safety of water quality.

Corrosion and anti-scaling

Acid and alkali resistance, strong chemical corrosion resistance, smooth inner wall, not easy to scale, long-term use of stable flow.

Hot melt connection, strong sealing

Adopting hot melt socket technology, there is no risk of leakage at the connection, and the integrated structure improves system reliability.

Lightweight and easy to construct

The weight is only 1/8 of that of metal pipes, which is convenient for transportation and installation, reducing labor costs.

Long life and low maintenance

The designed service life is more than 50 years, maintenance-free, and the overall cost is low.

Energy-saving and heat preservation

The thermal conductivity is low (only 1/200 of metal pipes), which reduces heat loss and is suitable for hot water systems.

(Plastic Water Poly HDPE Pipe Supply)

Specifications of Plastic Water Poly HDPE Pipe Supply

Here’s the item material on HDPE pipeline specifications:

Our plastic pipes make use of high-grade HDPE product. HDPE represents High-Density Polyethylene. This product is tough and long-lasting. It stands up to deterioration exceptionally well. Chemicals in soil or water won’t damage these pipes. They deal with influences without splitting conveniently. HDPE pipelines work accurately for many years underground.

We offer a complete series of sizes. Common diameters consist of 20mm, 25mm, 32mm, 40mm, 50mm, 63mm, 75mm, 90mm, 110mm, and larger. Wall surface thickness complies with standard SDR scores. SDR suggests Standard Measurement Ratio. It controls the pipe’s pressure capability. Lower SDR numbers imply thicker wall surfaces. Thicker wall surfaces deal with higher pressures.

Pressure scores are clearly marked. PN scores indicate small pressure. PN6, PN8, PN10, PN12.5, and PN16 are common. PN6 deals with 6 bar pressure. PN16 takes care of 16 bar stress. Choose the score matching your system requires. These pipelines endure surge pressures also.

Jointing is simple and secure. Butt fusion welding produces the toughest joints. Heated ends thaw together creating one solid piece. Electrofusion utilizes special fittings with built-in heating systems. Flanged joints benefit connections to shutoffs or pumps. Mechanical installations offer an additional choice. All techniques guarantee leak-free seals.

HDPE pipelines are really adaptable. They bend somewhat without needing additional installations. This simplifies installment around obstacles. Trench accounts can be narrower. Much less excavating means lower expenses. The pipes are also very light. Handling and transport are much easier than steel pipelines.

These pipes are excellent for many water applications. Utilize them for main water supply lines. They help distribution networks within towns. Industrial water transfer is one more usual use. Agricultural watering systems benefit significantly. Even trenchless installments like directional exploration are feasible. HDPE handles chilly safe and clean water flawlessly.

(Plastic Water Poly HDPE Pipe Supply)

Applications of Plastic Water Poly HDPE Pipe Supply

HDPE pipelines are difficult plastic pipes. They manage water supply quite possibly. Many places utilize them for tidy alcohol consumption water systems. Cities install them below ground for major lines. Towns use them for smaller sized neighborhood networks. These pipes withstand corrosion and chemicals. Water stays tidy and secure inside them. They last a long period of time underground without damaging down.

Farmers rely upon HDPE pipelines for watering. They relocate water across fields successfully. These pipelines are light and easy to manage. Employees mount them promptly over unequal ground. They do not leakage at connections. This conserves water and money. Animals or farm devices driving over hidden pipes hardly ever damage them. They flex a little without splitting.

Manufacturing facilities make use of HDPE pipelines for moving different liquids. They carry chemicals safely. They handle drainage without corroding. The smooth inside surface keeps circulation high. Pressure loss is marginal. This conserves power over long distances. Mines install HDPE pipelines for slurry transportation. They stand up to abrasive materials well. Employees don’t worry about leaks creating ecological problems.

Gas companies select HDPE pipes for gas circulation. They securely transport gas. The pipes are merged together. This creates a long-term, watertight seal. Underground, they resist ground motion and stress. Repair requirements are reduced. Energy trenches often hold HDPE pipelines for interaction wires also. They protect the cords from dampness and damages.

Land designers select HDPE for stormwater systems. They take care of rain runoff. These pipes deal with varying flow quantities. They are strong sufficient for deep burial under roads. Garbage dumps utilize them for leachate collection. They have contaminated fluids successfully.

Packing and Shipment

Depends on the products and qty,we could make the packing of coiling,rolls,bundle packing,crates or boxes,etc.

Shipment:By sea,railway,by air or as customer’s request.

Company Profile

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding HDPE Pipe Fitting, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net

Payment Terms

T/T,L/C at sight,Western Union & Paypal,etc.

5 FAQs of Plastic Water Poly HDPE Pipe Supply

Plastic Water Poly HDPE Pipe Supply FAQs

What makes HDPE pipe different from other pipes?

HDPE pipe is plastic pipe. It’s made from strong polyethylene plastic. This material is very tough. It resists chemicals well. HDPE won’t rust or corrode like metal pipes. It doesn’t rot like some older materials. This plastic pipe is also very flexible. It handles ground shifts well. It’s a good choice for many water projects.

What sizes do you offer?

We supply HDPE pipes in many sizes. Small diameters are available. Large diameters are available too. Common sizes include 20mm up to 1200mm. We stock standard sizes ready for quick delivery. Special sizes can be ordered. We meet most project needs.

How much pressure can these pipes handle?

HDPE pipes handle high water pressure. The exact pressure rating depends on the pipe. It depends on the wall thickness. It depends on the specific grade of HDPE. We offer pipes rated for different pressures. Low pressure systems use thinner pipes. High pressure mains use thicker, stronger pipes. Tell us your pressure needs. We find the right pipe for your job.

How are HDPE pipes joined together?

Joining HDPE pipe is reliable. The main method is heat fusion. This melts the pipe ends together. It creates a seamless, leak-proof joint. Butt fusion connects straight sections. Electrofusion uses special fittings with heating elements. Mechanical fittings are also an option. They allow connections to other pipe types. Heat fusion is the strongest method for permanent joints.

How long does HDPE pipe last?

HDPE pipe lasts a very long time. Its expected lifespan is over 50 years. Often it lasts much longer. The plastic resists environmental stress cracking. It doesn’t degrade from sunlight or soil chemicals. Properly installed HDPE systems provide decades of service. This durability means lower replacement costs later. It’s a long-term solution for water supply.

(Plastic Water Poly HDPE Pipe Supply)

REQUEST A QUOTE

RELATED PRODUCTS

Green Hot Cold Water Tube Ppr Pipe PN16 for Water Delivery

22mm Polypropylene Plastic Cable Conduit Customized Plastic Pipe PP Cable Management

Factory Plumbing Materials PPR Free Sample OEM White Color Plastic Polypropylene Ppr Pipe

PPR Pipes Manufactures Plastic Polypropylene Plumbing Materials Blue PPR Tube

Promotion Customized Professional Silicone Tubing High Temperature Resistant

100% New Imported PP Material PPR Pipe Hot Water Pipe Factory

- Email: sales@pipesandfittings.net

- WeChat: +86 18337900677