LUOYANG DATANG ENERGY TECH CO.,LTD

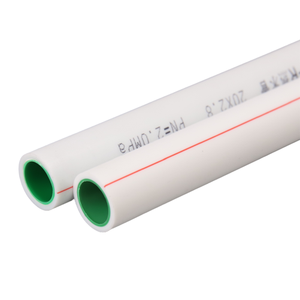

Virgin Injection Grade Extrusion Hot Cold Water Random Copolymer Molding Quality PP PPR Pipe

PRODUCT PARAMETERS

Description

Introduction of Virgin Injection Grade Extrusion Hot Cold Water Random Copolymer Molding Quality PP PPR Pipe

PPR pipe (full name Polypropylene Random Copolymer Pipe, is a high-performance plastic pipe made of high-quality random copolymer polypropylene raw materials. Due to its high temperature resistance, pressure resistance, environmental protection and non-toxicity, it is widely used in building hot and cold water systems, HVAC engineering, drinking water transportation and industrial fluid transmission, and is an ideal substitute for traditional metal pipes.

Characteristics and Features of Virgin Injection Grade Extrusion Hot Cold Water Random Copolymer Molding Quality PP PPR Pipe

High temperature and high pressure resistance

Long-term working temperature can reach 70°C, short-term high temperature resistance to 95°C, excellent pressure bearing performance (common pressure level PN20, PN25).

Environmental protection and health

The raw materials are pure and non-toxic, meet drinking water standards (such as FDA, EN ISO and other certifications), do not breed bacteria, and ensure the safety of water quality.

Corrosion and anti-scaling

Acid and alkali resistance, strong chemical corrosion resistance, smooth inner wall, not easy to scale, long-term use of stable flow.

Hot melt connection, strong sealing

Adopting hot melt socket technology, there is no risk of leakage at the connection, and the integrated structure improves system reliability.

Lightweight and easy to construct

The weight is only 1/8 of that of metal pipes, which is convenient for transportation and installation, reducing labor costs.

Long life and low maintenance

The designed service life is more than 50 years, maintenance-free, and the overall cost is low.

Energy-saving and heat preservation

The thermal conductivity is low (only 1/200 of metal pipes), which reduces heat loss and is suitable for hot water systems.

(Virgin Injection Grade Extrusion Hot Cold Water Random Copolymer Molding Quality PP PPR Pipe)

Specifications of Virgin Injection Grade Extrusion Hot Cold Water Random Copolymer Molding Quality PP PPR Pipe

Our PP PPR pipelines use virgin polypropylene random copolymer. This product makes sure high pureness. It has no recycled web content. The pipes match cold and hot water systems. They manage temperature levels up to 95 ° C for warm water. Cold water applications function completely as well.

Two grades are offered. Injection grade helps fittings and complicated parts. Extrusion grade makes continual pipeline sizes. Both qualities satisfy rigorous molding quality standards. This ensures constant wall thickness. It avoids vulnerable points.

Standard sizes range from 20mm to 110mm diameter. Pressure ratings cover 10, 16, and 20 bar choices. Select based on your system requires. The pipes resist chemical deterioration. They will not rust or scale internally. This maintains water circulation smooth for several years.

Installment is straightforward. The pipes fuse with each other using warm. This produces watertight joints. No unique devices are needed beyond a welding machine. The material remains flexible in cold conditions. It stays clear of breaking.

Safety accreditations include ISO 15874 and hubbub 8077/8078. These confirm reliability for alcohol consumption water. The pipes are likewise environmentally friendly. They create no contaminants when heated. Maintenance costs stay low. The smooth internal surface area minimizes friction. This saves pump power.

Shade options are green for cold water, white for warm. Both have blue recognition stripes. UV resistance is integrated for outdoor use. Expect a service life going beyond half a century. This assumes typical pressure problems.

Random copolymer structure gives additional strength. It deals with pressure rises better than basic PP. Thermal security protects against deformation. The pipes remain directly during operation. Sound transmission is very little. Water moves silently.

Quality checks occur at every stage. Basic material screening comes first. Then production surveillance follows. Lastly, each batch undertakes pressure examinations. We ensure zero problems.

(Virgin Injection Grade Extrusion Hot Cold Water Random Copolymer Molding Quality PP PPR Pipe)

Applications of Virgin Injection Grade Extrusion Hot Cold Water Random Copolymer Molding Quality PP PPR Pipe

PPR pipes are special plastic pipes produced water supply. They use premium virgin PP arbitrary copolymer material. This material originates from shot quality material. The pipelines are made through extrusion and molding processes. The result is a solid reliable product. These pipelines deal with chilly and hot water flawlessly.

You see these pipes in houses and structures. They lug alcohol consumption water safely. The pipes do not affect the water taste or top quality. They are good for the primary water lines inside wall surfaces or under floorings. They connect to sinks, showers, toilets.

Warm water systems make use of these pipelines as well. They collaborate with hot water heater and central heating boilers. They link radiators for home heating. The pipes resist high temperatures without warping. They last a very long time even with continuous hot water flow.

Manufacturing facilities and processing plants install these pipelines. They move water for cooling down equipment. They lug water for cleansing processes. The pipes withstand many chemicals discovered in industrial settings. They do not corrosion or corrode like steel pipes.

The smooth inside surface area aids water flow quickly. This minimizes stress loss. The pipelines are light. This makes them very easy to deliver and install. Workers save time and effort. The joints are solid. They utilize warm combination welding. This produces a permanent leak evidence seal. The pipes remain silent. They do not make sounds from water hammer.

These pipelines manage stress adjustments well. They are tough versus influences. They do not split quickly in cold weather. The material remains adaptable. Maintenance is easy. They need little upkeep over many years. The pipes provide a cost effective solution for reputable water shipment.

Packing and Shipment

Depends on the products and qty,we could make the packing of coiling,rolls,bundle packing,crates or boxes,etc.

Shipment:By sea,railway,by air or as customer’s request.

Company Profile

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding HDPE Pipe Fitting, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net

Payment Terms

T/T,L/C at sight,Western Union & Paypal,etc.

5 FAQs of Virgin Injection Grade Extrusion Hot Cold Water Random Copolymer Molding Quality PP PPR Pipe

What is PP PPR pipe? PP PPR pipe is plastic tubing made from polypropylene random copolymer. It handles water in plumbing systems. The material is tough. It works for both heating and cooling applications. Builders and plumbers choose it often.

What are the main uses? This pipe moves drinking water in homes and offices. It fits underfloor heating systems. It connects radiators. Factories use it for industrial water lines. Farms employ it for irrigation setups.

Why choose virgin material? Virgin polypropylene is pure. It has no recycled content. This makes the pipe stronger. It prevents cracks. The material stays safe for drinking water. It avoids chemical contamination.

How does random copolymer molding help? This method changes the plastic structure. It adds flexibility. The pipe bends without breaking. It withstands high pressure. Temperature swings cause less stress. The result is fewer leaks.

What are the advantages for hot and cold water? The pipe resists heat up to high temperatures. It won’t corrode or rust. Mineral buildup stays minimal inside. Installation is simple with heat fusion joints. The lightweight design cuts labor time. Energy efficiency improves because insulation is good.

(Virgin Injection Grade Extrusion Hot Cold Water Random Copolymer Molding Quality PP PPR Pipe)

REQUEST A QUOTE

RELATED PRODUCTS

High Quality Material Ppr Pipe Cold Water Sizes Chart Polypropylene Random Hot Melting

Plastic Water Poly HDPE Pipe Supply

Hdpe Pipe Full Form Per Foot Polyethylene Tube Sdr11 List

Origin Direct PPR Pipe List For Building Construction

All Types and Uses of PPR Pipes and Fittings

Cheap Plastic PPR Tube Water Supply 20-160MM Green Pure PPR Pipe

- Email: sales@pipesandfittings.net

- WeChat: +86 18337900677