LUOYANG DATANG ENERGY TECH CO.,LTD

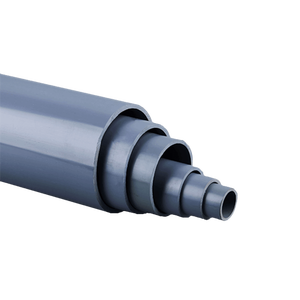

Plastic Virgin PVC Resin Raw Material Polyvinyl Chloride Pipe Grade

PRODUCT PARAMETERS

Description

Introduction of Plastic Virgin PVC Resin Raw Material Polyvinyl Chloride Pipe Grade

Polyvinylchloride (PVC) Pipe is a durable, lightweight, and cost-effective piping solution widely used in industrial, agricultural, construction, and plumbing applications. Made from high-quality polyvinyl chloride material, PVC pipes offer excellent corrosion resistance, smooth inner walls for efficient fluid flow, and long-term reliability in various environments.

Key Features of Plastic Virgin PVC Resin Raw Material Polyvinyl Chloride Pipe Grade

Corrosion & Chemical Resistance

Resistant to rust, chemicals, and acidic/alkaline substances, making them ideal for industrial and wastewater applications.

Lightweight & Easy Installation

Lightweight design reduces transportation and labor costs, while simple joining methods (e.g., solvent welding, threading) ensure quick installation.

Smooth Interior Surface

Minimizes friction loss, improving flow efficiency and reducing energy consumption in fluid transport systems.

High Strength & Durability

Withstands high pressure and impact, suitable for underground and above-ground installations.

Long Service Life

UV-resistant (if formulated) and unaffected by moisture, ensuring decades of low-maintenance operation.

Cost-Effective

Lower material and installation costs compared to metal pipes, providing an economical alternative.

Non-Toxic & Safe

Certified for potable water supply (lead-free formulations available) and compliant with international standards (e.g., NSF, ASTM).

Versatile Applications

Used in water supply, drainage, irrigation, electrical conduits, and industrial processing systems.

(Plastic Virgin PVC Resin Raw Material Polyvinyl Chloride Pipe Grade)

Specifications of Plastic Virgin PVC Resin Raw Material Polyvinyl Chloride Pipe Grade

Plastic virgin PVC material resources is polyvinyl chloride for pipe production. This product is white powder. It has specific homes for making solid pipelines. The K-value range is very important. It is usually in between 66 and 68. This K-value controls the product’s viscosity during handling. It affects the last pipe stamina. The evident density is one more essential spec. It drops in between 0.49 and 0.55 grams per cubic centimeter. This thickness effects how the powder streams in the equipment. It influences storage quantity also.

Fragment dimension matters a whole lot. Over 90% of the powder goes through a 60-mesh screen. This great fragment dimension ensures excellent mixing. It helps the product feed smoothly right into extruders. The volatile matter content is very low. It is less than 0.4%. Low wetness avoids problems like bubbles in the last pipe. Excellent thermal stability is necessary. The material has to withstand high temperatures throughout extrusion without deteriorating. Examinations confirm security times going beyond 10 minutes at 190 ° C.

The pureness level is high. It mores than 99.5% polyvinyl chloride. Impurities are lessened. This pureness guarantees constant efficiency and toughness. VCM residue is strictly controlled. It is below 1 component per million. This makes the material risk-free for drinkable pipes. The powder is free-flowing. It does not glob easily. This characteristic is vital for computerized assembly line. Mass thickness is optimized for effective transport and handling. The material satisfies worldwide requirements for pipeline grade materials. These consist of ISO and ASTM requirements. Producers rely on these regular specs. They assure the material carries out well in pipeline extrusion equipments. The resulting pipes have high stress resistance. They reveal exceptional chemical resistance. Lasting efficiency in water supply is dependable. Quality assurance checks every set. This ensures the specs are always met. Pipe manufacturers obtain a dependable resources.

(Plastic Virgin PVC Resin Raw Material Polyvinyl Chloride Pipe Grade)

Applications of Plastic Virgin PVC Resin Raw Material Polyvinyl Chloride Pipe Grade

Virgin PVC resin is a raw material. It’s polyvinyl chloride in its pure form. This pipe grade resin is essential for making strong plastic pipes. Manufacturers use it because it’s reliable and cost-effective. The material has excellent properties for pipe production. It resists chemicals very well. It handles high pressure without breaking. It doesn’t corrode like metal pipes. This makes it last a long time.

Water supply systems use PVC pipes widely. Cities install them for clean drinking water distribution. Homes and buildings rely on these pipes for daily use. They are safe for transporting potable water. The material doesn’t affect water quality. PVC pipes are also lightweight. Workers install them faster than heavy metal alternatives. This saves time and labor costs.

Sewage and drainage applications depend on PVC too. The pipes manage wastewater efficiently. They handle harsh sewage chemicals without damage. Municipalities choose PVC for sewer lines because it prevents leaks. Its smooth interior stops waste buildup. Stormwater systems use these pipes for rainwater management. Farms employ PVC pipes in irrigation networks. They deliver water to crops consistently. The pipes resist sun damage and soil chemicals.

Plumbing in residential and commercial buildings uses PVC extensively. It’s common for vent lines and waste drains. Builders prefer it for its easy installation. Electrical conduits made from PVC protect wiring safely. They shield cables from moisture and physical harm. Industrial plants install PVC pipes for chemical transport. The material withstands aggressive substances.

PVC pipes work well in underground installations. They endure soil pressure and shifting ground. Their joint systems create secure, leak-proof connections. Repair needs are minimal over decades of use. This reliability reduces maintenance costs. Construction projects choose PVC for these advantages. The material supports sustainable infrastructure development globally.

Packing and Shipment

Depends on the products and qty,we could make the packing of coiling,rolls,bundle packing,crates or boxes,etc.

Shipment:By sea,railway,by air or as customer’s request.

Company Profile

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding HDPE Pipe Fitting, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net

Payment Terms

T/T,L/C at sight,Western Union & Paypal,etc.

5 FAQs of Plastic Virgin PVC Resin Raw Material Polyvinyl Chloride Pipe Grade

PVC resin is a white powder. It’s the main raw material for PVC pipes. Manufacturers make it by polymerizing vinyl chloride. This resin is thermoplastic. It softens with heat. It hardens when cooled. This allows shaping into pipes.

Virgin PVC resin is unused material. It has no recycled content. Pipes need virgin resin. It ensures consistent quality. Recycled resin might have impurities. Impurities weaken pipes. Virgin resin gives better strength. It also improves chemical resistance.

Good pipe quality depends on PVC resin. High-grade resin has uniform particles. Uniformity means even melting. This prevents weak spots in pipes. Resin purity matters too. Pure resin resists cracks. It handles pressure better. Resin quality affects pipe lifespan.

Store PVC resin in dry places. Moisture ruins the resin. Keep it away from sunlight. Sunlight degrades the material. Use sealed containers. Prevent dust contamination. Ideal storage temperature is room temperature. Avoid heat sources nearby.

Making pipes starts with mixing. Combine PVC resin with stabilizers. Add lubricants and pigments. Heat the mixture in an extruder. The resin melts into a dough. Force the dough through a mold. This shapes the pipe. Cool the pipe in water. Cut it to required lengths. Test the pipes before use.

(Plastic Virgin PVC Resin Raw Material Polyvinyl Chloride Pipe Grade)

REQUEST A QUOTE

RELATED PRODUCTS

Quality PVC Blue Lay Flat Water Pipe for Pool Pump Agricultural Irrigation

ASTM D1785/2466 4 Inch Diameter PVC Underground Water Supply Plastic Pipe Sizes

ing Transparent PVC Hard Pipe Factory Multiple Size Pipes

Quality Soft Plastic Tube Package Transparent Plastic PVC PP Pipe Polypropylene Tubing

UPVC Pipe for Water Supply PVC Plastic Tube 1/2″-14″ America Standard

Voltage Power Cable Protection PVC Pipe Good Heat Resistance Electrical Conduit Plastic Tubes

- Email: sales@pipesandfittings.net

- WeChat: +86 18337900677