LUOYANG DATANG ENERGY TECH CO.,LTD

Factory Api 5l Welded Pipe Q345 10# 20# Weld Tube Carbon Steel Pipe

PRODUCT PARAMETERS

Description

Overview of Factory Api 5l Welded Pipe Q345 10# 20# Weld Tube Carbon Steel Pipe

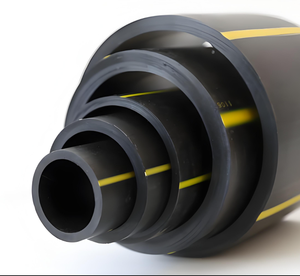

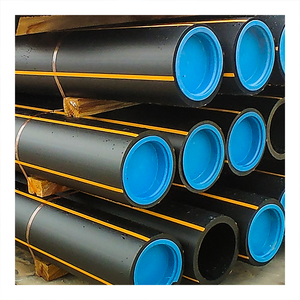

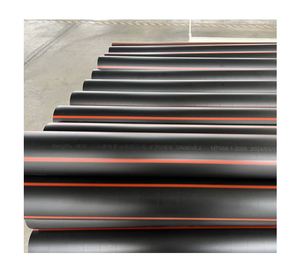

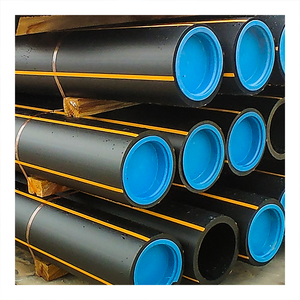

Factory Api 5l Welded Pipe Q345 10# 20# Weld Tube Carbon Steel Pipe is designed for efficient and secure gas transportation in residential, commercial, and industrial applications. Made from durable materials such as carbon steel, stainless steel, or PE polyethylene, our gas pipes ensure leak-proof performance and long-term reliability. Whether for natural gas, propane, or other fuel gases, our products meet strict industry standards for safety and efficiency.

Features of Factory Api 5l Welded Pipe Q345 10# 20# Weld Tube Carbon Steel Pipe

Corrosion-Resistant – Engineered to withstand harsh environments and prevent leaks.

High Pressure and Temperature Tolerance – Suitable for demanding gas distribution systems.

Lightweight and Flexible PE Pipes – Easy to install with excellent durability.

Leak-Proof Joints – Precision welding and threading for secure connections.

Compliant with Safety Standards – Certified for reliable performance in gas applications.

(Factory Api 5l Welded Pipe Q345 10# 20# Weld Tube Carbon Steel Pipe)

Specifications of Factory Api 5l Welded Pipe Q345 10# 20# Weld Tube Carbon Steel Pipe

This factory produces API 5L welded pipes. These pipes carry oil and gas. They are made from carbon steel. Three common grades are Q345, 10#, and 20#. Each grade suits different needs.

The API 5L standard is important. It sets rules for pipe quality. It ensures pipes are safe and reliable. These pipes meet this standard. They are suitable for pipeline systems.

Q345 steel offers good strength. It handles higher pressure well. This grade is common in demanding projects. It provides a solid balance of strength and toughness.

10# steel is a lower carbon grade. It is easier to form and weld. It works well for less demanding pressure situations. This grade is often more cost-effective.

20# steel is another common choice. It has slightly more carbon than 10#. It provides better strength than 10#. It is widely used in general industrial applications.

The pipes have specific material properties. Yield strength and tensile strength are key measures. Q345 has the highest strength. 10# has the lowest. 20# sits in the middle. Chemical composition matters too. Carbon, manganese, silicon, sulfur, and phosphorus levels are controlled. This control ensures performance and weldability.

Standard pipe sizes are available. Outer diameters range widely. Wall thickness varies based on the schedule. Common schedules include SCH 40 and SCH 80. Lengths are usually 6 meters or 12 meters. Custom lengths are possible.

The pipes are welded longitudinally. This means the seam runs straight along the pipe. Modern welding methods ensure a strong, consistent seam. The pipes undergo testing. Hydrostatic tests check for leaks. Non-destructive tests examine the weld seam integrity. Dimensions are carefully checked. Surface finish is inspected.

These pipes connect systems. They transport fluids safely. They are used in oil fields, gas distribution, water projects, and structural applications. Choosing the right grade depends on the required pressure and service conditions.

(Factory Api 5l Welded Pipe Q345 10# 20# Weld Tube Carbon Steel Pipe)

Applications of Factory Api 5l Welded Pipe Q345 10# 20# Weld Tube Carbon Steel Pipe

Factory API 5L welded pipes are essential steel tubes. They move fluids and gases safely under pressure. Common grades include Q345, 10#, and 20# carbon steel. These grades offer good strength and weldability. This makes them suitable for many demanding jobs.

The oil and gas industry uses these pipes heavily. They transport crude oil from wells. They carry natural gas over long distances. They work in gathering lines and transmission pipelines. Their strength handles high pressure underground or above ground. They are reliable for these critical energy networks.

Construction projects need these pipes too. They form structural supports in buildings. They are part of large frameworks and bridges. Builders use them for scaffolding systems. Their durability supports heavy loads safely. This makes construction sites more efficient.

Water systems depend on these welded pipes. They are key for municipal water supply lines. They carry drinking water to homes and businesses. They handle wastewater removal effectively. Treatment plants use them for moving water. Irrigation systems rely on them for distributing water to farms. They resist corrosion well in these wet environments.

Factories use these pipes extensively. They create conveyor system frames. They build machine guards and safety cages. They form handrails and walkways. They are vital for material handling equipment. Their consistent quality ensures smooth factory operations.

Mechanical engineering applications are common. These pipes work as hydraulic cylinder barrels. They form parts for presses and other heavy machinery. They are used for compressed air lines inside plants. Their precise dimensions fit engineering designs perfectly.

These pipes are also chosen for general fabrication. Workshops use them for custom frames and supports. They build storage racks and workbenches. They make fencing and gates strong. Fabricators appreciate their ready availability and good performance.

Packing and Shipment

Depends on the products and qty,we could make the packing of coiling,rolls,bundle packing,crates or boxes,etc.

Shipment:By sea,railway,by air or as customer’s request.

Company Profile

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding HDPE Pipe Fitting, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net

Payment Terms

T/T,L/C at sight,Western Union & Paypal,etc.

5 FAQs of Factory Api 5l Welded Pipe Q345 10# 20# Weld Tube Carbon Steel Pipe

What exactly are these pipes?

These are welded steel tubes. They meet API 5L standards. This means they are good for oil and gas pipelines. They are made from carbon steel grades Q345, 10#, or 20#. The pipes are strong and durable.

What’s the difference between Q345, 10#, and 20# steel?

The grades refer to different steel compositions. Q345 is a low-alloy steel. It has higher yield strength. 10# and 20# are carbon steels. 20# has slightly more carbon than 10#. This affects strength and weldability. Choose the grade based on your project pressure needs.

Why is API 5L certification important?

API 5L is a key standard. It ensures the pipes are safe for transporting oil and gas. Certified pipes pass strict tests. These tests check strength, chemistry, and dimensions. Using API 5L pipes reduces project risks.

What sizes are available?

These welded pipes come in many sizes. Outer diameters range from small to large. Wall thicknesses vary too. Common options are listed in product specs. Check the specs for exact sizes needed for your job.

How is quality controlled?

Factories use strict checks. They inspect the steel material first. The welding process is monitored closely. Finished pipes undergo tests. Common tests include hydrostatic pressure tests and visual checks. This ensures the pipes are defect-free.

(Factory Api 5l Welded Pipe Q345 10# 20# Weld Tube Carbon Steel Pipe)

REQUEST A QUOTE

RELATED PRODUCTS

High Quality 5/16″ 8mm Orange PVC LPG Gas Hose Pipe Flexible Soft Orange PVC Plastic Propane LPG Gas Pipe

Adjustable Brass Nitrogen Gas Pipe with Two Pressure Gauges System Line Nalve Regulator for Oxygen CO2 and Helium Gas

Carbon Steel Pipe Seamless Metal Gas Pipeline Durable and Versatile Metal Product

ASTM A106 A53 GrB API 5L Gr.B Seamless Carbon Steel Pipe Casing Pipe Good Per Ton

Hot Dip Greenhouse Construction Carport 200mm 6 Inch Schedule 40 Resistant Galvanized Steel Round Pipe Tube

S355 JR 200*200*12 Mm Carbon Steel Tube Steel Metal Tube Black Hollow Section SHS RHS Welded Steel Square Pipe

- Email: sales@pipesandfittings.net

- WeChat: +86 18337900677