LUOYANG DATANG ENERGY TECH CO.,LTD

API 5L SSAW/LSAW Spiral Welded Carbon Steel Pipe Natural Gas and Oil Pipeline

PRODUCT PARAMETERS

Description

Overview of API 5L SSAW/LSAW Spiral Welded Carbon Steel Pipe Natural Gas and Oil Pipeline

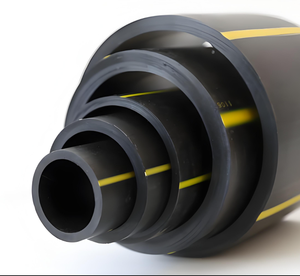

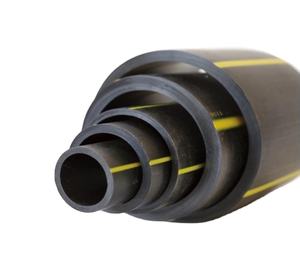

API 5L SSAW/LSAW Spiral Welded Carbon Steel Pipe Natural Gas and Oil Pipeline is designed for efficient and secure gas transportation in residential, commercial, and industrial applications. Made from durable materials such as carbon steel, stainless steel, or PE polyethylene, our gas pipes ensure leak-proof performance and long-term reliability. Whether for natural gas, propane, or other fuel gases, our products meet strict industry standards for safety and efficiency.

Features of API 5L SSAW/LSAW Spiral Welded Carbon Steel Pipe Natural Gas and Oil Pipeline

Corrosion-Resistant – Engineered to withstand harsh environments and prevent leaks.

High Pressure and Temperature Tolerance – Suitable for demanding gas distribution systems.

Lightweight and Flexible PE Pipes – Easy to install with excellent durability.

Leak-Proof Joints – Precision welding and threading for secure connections.

Compliant with Safety Standards – Certified for reliable performance in gas applications.

(API 5L SSAW/LSAW Spiral Welded Carbon Steel Pipe Natural Gas and Oil Pipeline)

Specifications of API 5L SSAW/LSAW Spiral Welded Carbon Steel Pipe Natural Gas and Oil Pipeline

API 5L SSAW and LSAW pipes are essential for moving natural gas and oil over long distances. These pipes use carbon steel. They meet strict API 5L standards. This ensures reliability for pipeline projects.

These pipes come in various strength grades. Common grades include B, X42, X46, X52, X56, X60, X65, X70, and X80. The grade tells you the pipe’s yield strength. Higher grades handle greater pressures. You need the right grade for your project’s pressure needs.

Diameter options are wide. SSAW pipes typically range from 20 inches up to 100 inches. LSAW pipes often cover 16 inches to 60 inches. Wall thickness also varies significantly. Thicker walls manage higher internal pressures. Choose the size and wall thickness based on your flow rate and pressure requirements.

Manufacturing involves forming steel plates or coils into a cylinder. The seam is welded spirally. This spiral weld design gives the pipe good strength. It allows large diameters. The process must follow API 5L welding procedures exactly. Quality control is critical during welding.

The pipes undergo rigorous testing. Hydrostatic testing checks pressure resistance. Non-destructive testing examines the weld seam integrity. Dimensional checks confirm size accuracy. Mechanical tests verify the steel’s strength and toughness. Chemical analysis confirms the material composition. These tests guarantee the pipe performs safely.

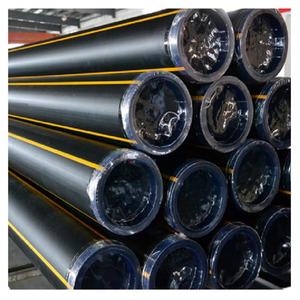

Protection against corrosion is vital. Pipes often get external coatings. Common coatings are FBE (Fusion Bonded Epoxy) or 3LPE (Three-Layer Polyethylene). These coatings shield the pipe from soil and moisture. Internal coatings are sometimes used too. This depends on the fluid being transported.

These pipes handle demanding conditions. They transport natural gas and crude oil under high pressure. They are used in cross-country transmission lines. They are also used for gathering lines and distribution networks. Their strength and durability make them suitable for challenging environments.

Material properties are strictly controlled. The steel offers good toughness. It resists cracking. It performs well even at low temperatures. The pipes are built for long-term service underground or underwater.

(API 5L SSAW/LSAW Spiral Welded Carbon Steel Pipe Natural Gas and Oil Pipeline)

Applications of API 5L SSAW/LSAW Spiral Welded Carbon Steel Pipe Natural Gas and Oil Pipeline

API 5L SSAW and LSAW spiral welded carbon steel pipes are essential for moving natural gas and oil long distances. These pipes are built tough. They meet strict API 5L standards for strength and safety in pipelines. Their spiral weld design creates a strong structure. This strength handles the high pressures inside oil and gas pipelines.

Moving crude oil or refined products over land relies heavily on these pipes. They are cost-effective for big, long-distance projects. Their ability to handle high internal pressure makes them perfect. They resist the stresses of pumping oil hundreds or thousands of miles. The steel construction also fights corrosion well over time.

Transporting natural gas demands large diameter pipes. SSAW and LSAW pipes excel here. They are readily available in the big sizes needed for major gas transmission lines. Their inherent strength ensures stability underground. They safely contain the gas under pressure across varied landscapes.

These pipes are also vital for crossing difficult areas. They perform reliably under rivers, lakes, or wetlands. Their durability withstands the extra stress from water pressure and shifting ground. Building pipelines across mountains, deserts, or soft soil is easier with them. Their flexibility during installation helps navigate uneven terrain smoothly.

Urban and industrial areas need secure energy delivery. API 5L SSAW/LSAW pipes form the backbone of these local distribution networks. They reliably bring gas or oil to homes, businesses, and factories. Their consistent quality, proven by strict testing, ensures safe operation near populated zones.

Packing and Shipment

Depends on the products and qty,we could make the packing of coiling,rolls,bundle packing,crates or boxes,etc.

Shipment:By sea,railway,by air or as customer’s request.

Company Profile

Luoyang Datang Energy Tech Co., Ltd. is a leading Chinese manufacturer specializing in high-quality plastic pipes and fittings. Equipped with state-of-the-art automated production lines and supported by a team of 200 professionals, we offer an extensive product line comprising over 150 types of plastic pipes and fittings designed for water supply and drainage systems, gas transmission, and floor heating systems. Our main products include PVC Pipes and Fittings, PE (HDPE) Pipes and Fittings, PPR Pipes and Fittings, and PEX Floor Heating Pipes.

Should you have any inquiries regarding HDPE Pipe Fitting, please do not hesitate to contact us!

Tel.:0086-183 3790 0677

Wechat: 0086-183 3790 0677

Whatsapp: 0086-183 3790 0677

Email: sales@pipesandfittings.net

Payment Terms

T/T,L/C at sight,Western Union & Paypal,etc.

5 FAQs of API 5L SSAW/LSAW Spiral Welded Carbon Steel Pipe Natural Gas and Oil Pipeline

What are API 5L SSAW and LSAW pipes?

These are big steel pipes for moving oil and gas underground or underwater. SSAW pipes have a spiral weld. LSAW pipes have a straight weld. Both types are made to strict API 5L rules. These rules ensure the pipes are strong and safe.

Where are these pipes mostly used?

They are built for big jobs. They form the main lines in oil and gas networks. You see them carrying oil and gas over long distances. They are good for high-pressure systems. They are also used for water pipelines sometimes.

Why use API 5L pipes for oil and gas?

The API 5L standard is key. It guarantees the steel quality and pipe strength. It ensures the pipes handle high pressure safely. It also makes sure the pipes resist cracking and corrosion. This standard is recognized everywhere for pipeline safety.

Can these pipes handle high pressure?

Yes. That’s a main reason they are used. Their design and steel strength allow them to work under very high pressure. The specific pressure rating depends on the pipe size, wall thickness, and steel grade. Always check the specifications for the exact pressure rating needed.

How do I know I’m getting good pipes?

Buy from reputable mills certified to API 5L. Ask for the mill test certificates. These papers prove the pipe meets the API 5L requirements. They show the chemical makeup and physical strength tests. Good suppliers provide this documentation.

(API 5L SSAW/LSAW Spiral Welded Carbon Steel Pipe Natural Gas and Oil Pipeline)

REQUEST A QUOTE

RELATED PRODUCTS

Galvanized Steel Pipe Ssaw Steel Pipe Tube For Oil And Gas Industry

High Quality Gas Pipe for Gas Appliances Stainless Steel Corrugated Pipe

ASTM A106/A53/A333 4130 Sch40 BS3602 Hot Rolled/Carbon/Alloy Seamless Steel Tube/Pipe for Oil Gas Pipeline Construction

China Carbon Steel Pipe Seamless Hot Rolled Steel Tube 20# Carbon Steel Pipe

Q235 Steel Tube Seamless Steel Carbon Pipe

ASTM A106 Grade B Seamless Carbon Steel Pipes Oil And Gas Pipes And Tubes Sch 40 80

- Email: sales@pipesandfittings.net

- WeChat: +86 18337900677